- This topic is empty.

-

AuthorPosts

-

2026-01-21 at 5:48 pm #27448

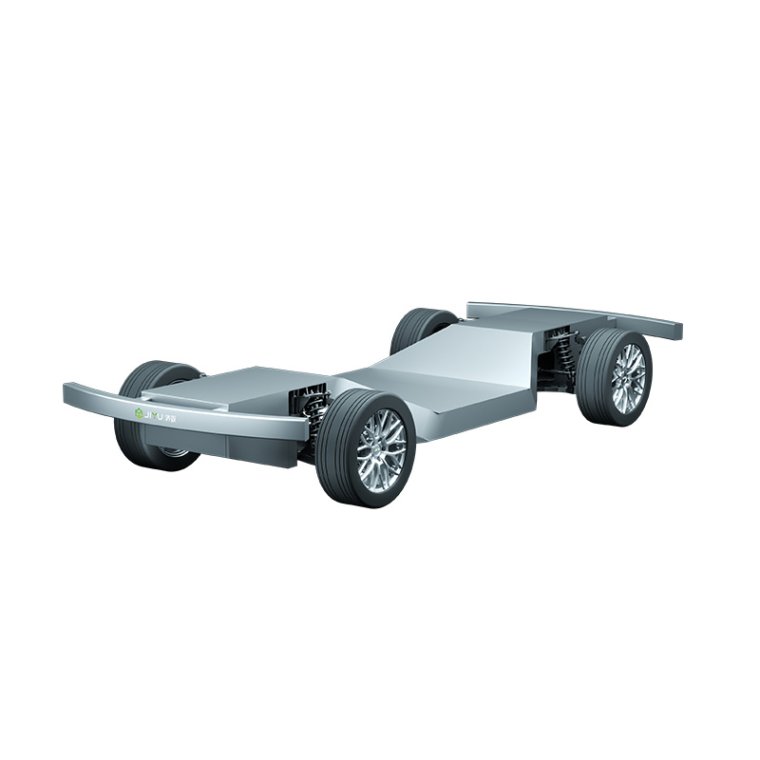

The automotive industry is undergoing a major transformation, driven by electric vehicles, autonomous driving, and smart mobility solutions. At the heart of many of these innovations is the modular drive-by-wire chassis—a flexible, electronically controlled platform that replaces traditional mechanical linkages with digital control systems. Understanding its architecture, components, and key benefits is essential for manufacturers, fleet operators, and innovators exploring next-generation vehicle technologies.

Understanding Modular Drive-by-Wire Chassis

A modular drive-by-wire chassis is a vehicle platform where critical functions—steering, braking, throttle, and suspension—are controlled electronically rather than mechanically. This system replaces conventional hydraulic or mechanical connections with sensors, actuators, and electronic control units (ECUs) that communicate via high-speed networks.

The modularity aspect refers to the chassis’ ability to be adapted across multiple vehicle types and configurations. This flexibility allows manufacturers to use the same basic chassis platform for electric delivery vehicles, autonomous passenger cars, unmanned logistics robots, and specialized commercial vehicles, significantly reducing development costs and time to market.

Core Architecture of a Drive-by-Wire Chassis

The architecture of a modular drive-by-wire chassis generally includes:

-

Electronic Control Units (ECUs): The central brain of the system, ECUs process input from sensors, manage actuators, and ensure safe operation. Redundancy and fail-safe mechanisms are critical to ensure reliability in autonomous or unmanned applications.

-

Sensors and Feedback Devices: These components monitor vehicle speed, wheel angle, suspension travel, braking pressure, and environmental conditions. Sensors provide real-time feedback to the ECUs for precise control.

-

Actuators: Electronic actuators replace mechanical linkages, executing steering, braking, acceleration, and suspension adjustments. High-performance actuators enable fast response times and accurate maneuvering.

-

High-Speed Communication Networks: Drive-by-wire systems rely on robust networks (e.g., CAN, Ethernet, FlexRay) to connect sensors, ECUs, and actuators seamlessly. Low latency and high reliability are essential to maintain vehicle stability.

-

Modular Chassis Structure: The physical platform is designed to accommodate different vehicle bodies, payloads, and applications without significant redesign. Battery packs, motors, and other components can be integrated into the modular frame efficiently.

Key Benefits of Modular Drive-by-Wire Chassis

1. Flexibility Across Vehicle Types

Modular chassis allow manufacturers to deploy a single platform across multiple vehicle configurations. This is particularly valuable in electric and autonomous vehicle development, where different vehicles share the same drive-by-wire architecture but vary in size, payload, or function.2. Enhanced Safety and Precision

Electronic control systems provide faster, more accurate responses than mechanical linkages. Advanced sensor fusion and real-time ECU processing allow for precise steering, braking, and acceleration control, which is especially important in autonomous or unmanned commercial vehicles.3. Reduced Complexity and Weight

By eliminating mechanical linkages and hydraulic systems, drive-by-wire chassis reduce vehicle complexity, weight, and maintenance requirements. This contributes to improved energy efficiency and longer service life.4. Customization for Unmanned and Autonomous Applications

Companies like Jiyu Technology specialize in developing modular drive-by-wire chassis for a wide range of autonomous applications, including unmanned logistics, last-mile delivery, disinfection vehicles, special-purpose unmanned vehicles, and passenger EVs. Their expertise in custom chassis solutions ensures that each vehicle meets the specific operational and environmental requirements of its intended use.5. Scalability and Future-Proofing

A modular approach allows for easy upgrades as new sensors, ECUs, and battery technologies emerge. This ensures vehicles can adapt to evolving autonomous driving software, AI capabilities, and electric powertrain improvements.Jiyu Technology’s Role in Modular Drive-by-Wire Innovation

Jiyu Technology stands out as a leader in modular drive-by-wire chassis solutions. The company possesses full capabilities for independent research, testing, and mass production of drive-by-wire platforms. With a focus on versatile, universal chassis architectures, Jiyu Technology has introduced multiple specifications of drive-by-wire chassis suitable for a variety of unmanned commercial scenarios. Additionally, their custom chassis services allow clients to deploy specialized solutions for logistics, delivery, sanitation, and passenger applications efficiently and reliably.

Conclusion

The modular drive-by-wire chassis represents a major step forward in vehicle platform design, offering flexibility, precision, and safety that traditional mechanical systems cannot match. For companies seeking to enter autonomous or electric mobility markets, partnering with professional developers like Jiyu Technology ensures access to high-quality, customizable drive-by-wire chassis that support a wide range of commercial and passenger applications. This modular, scalable, and electronically controlled approach is shaping the future of smart mobility and autonomous transportation.

http://www.jiyudrivebywire.com

Shanghai Jiyu Technology Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.