- This topic is empty.

-

AuthorPosts

-

2025-12-30 at 11:54 am #27251

Direct-to-garment (DTG) printing has become a core production method for brands seeking high-definition graphics, short production cycles, and flexible customization. However, achieving consistent results at scale requires more than advanced printers. True seamless customization depends on how fabric sourcing, pattern making, quality control, and export packaging are integrated into a single manufacturing workflow.

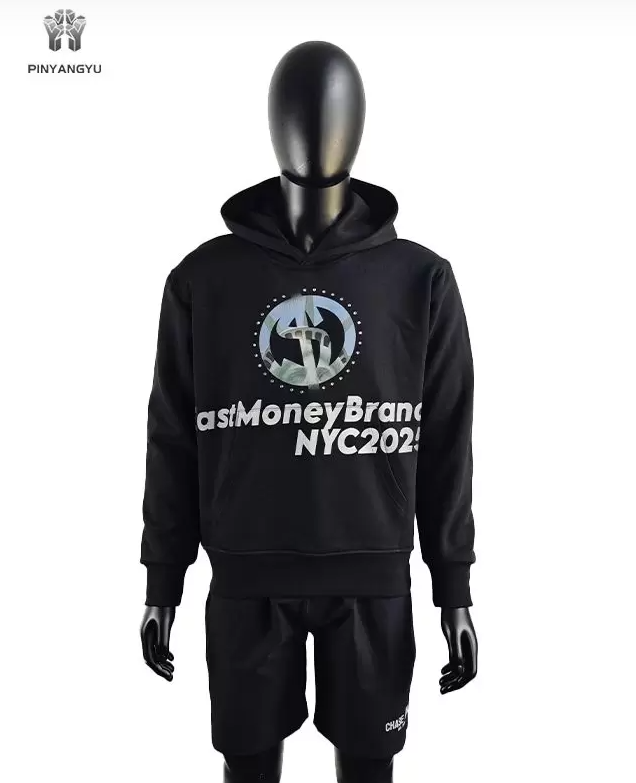

Pinyang Clothing delivers this integration through professional garment manufacturing experience, strong vertical supply chain control, and full-package OEM & ODM services—enabling DTG printing hoodies to move efficiently from concept to global distribution.

Fabric Sourcing Optimized for DTG Printing Performance

In DTG hoodie production, fabric selection directly determines print clarity, color saturation, wash durability, and hand feel. Unlike screen printing, DTG inks interact deeply with fiber composition and surface structure, making fabric sourcing a critical technical step rather than a procurement formality.

Pinyang Clothing sources and evaluates fabrics based on DTG-specific requirements, including:

-

Cotton content and fiber uniformity for ink absorption

-

Knit density consistency to avoid color variance

-

Surface smoothness to ensure fine graphic resolution

-

Shrinkage control to maintain print alignment after washing

With in-house fabric sourcing and procurement capabilities, Pinyang ensures material consistency across sampling and bulk production. This reduces common DTG issues such as uneven ink penetration or post-wash distortion, which remain key challenges for brands scaling DTG hoodies.

Industry data from textile testing institutions shows that fabric inconsistency accounts for over 35% of DTG print quality defects in mass production, reinforcing the importance of controlled sourcing.

Pattern Making Aligned with DTG Print Placement Accuracy

DTG printing demands high positional accuracy. Graphic placement must remain consistent across sizes, production batches, and garment styles. This places pattern making at the center of DTG hoodie customization rather than treating it as a separate design step.

Pinyang Clothing’s custom pattern making and sample development teams align patterns with:

-

DTG print zones on front, back, sleeves, and pockets

-

Size grading that preserves graphic proportions

-

Seam positions that avoid print distortion

Patterns are developed with print-first logic, ensuring that when hoodies move into cutting and sewing, the DTG artwork remains visually balanced and production-ready. This approach significantly reduces rework during printing and finishing.

Prototype Sampling as a Print Validation Process

Sampling is not only about fit and construction. In DTG hoodie manufacturing, prototype sampling functions as a print validation stage.

Pinyang Clothing supports prototype sampling starting from one piece, allowing brands to verify:

-

Color accuracy across different fabric lots

-

Ink fixation after curing and washing

-

Interaction between fabric stretch and print integrity

Sampling feedback is systematically applied before bulk production, protecting print quality and minimizing costly mid-production adjustments.

Integrated Production Workflow for DTG Hoodies

Seamless customization requires tight coordination between printing, cutting, sewing, and finishing. Pinyang Clothing’s full-package production model ensures that DTG printing is embedded within a unified manufacturing flow rather than treated as an isolated process.

Integrated production includes:

-

Pre-print garment preparation

-

Controlled DTG printing environment

-

Precision cutting aligned with print layout

-

Sewing and finishing designed to protect print surfaces

This vertically integrated structure reduces handling errors and maintains print consistency from the first unit to large-scale orders exceeding 10,000 pieces.

Quality Control Focused on DTG-Specific Risks

Quality control in DTG hoodie production extends beyond visual inspection. Pinyang Clothing implements DTG-focused quality checks throughout the production cycle.

Key inspection points include:

-

Ink adhesion and curing stability

-

Color fastness and wash resistance

-

Fabric recovery after printing

-

Print surface integrity after sewing and finishing

According to apparel quality benchmarks, DTG-related returns are often caused by insufficient curing or fabric-print incompatibility. Pinyang’s uncompromising quality assurance framework addresses these risks proactively, ensuring repeatable quality for long-term brand programs.

Export Packaging Designed to Protect DTG Prints

DTG prints are more sensitive to pressure, friction, and moisture during transportation. Export packaging is therefore a functional extension of the production process.

Pinyang Clothing’s export packaging and logistics management includes:

-

Protective folding methods to avoid print cracking

-

Moisture-resistant inner packaging

-

Print-safe stacking and carton specifications

-

Compliance with international shipping standards

By aligning packaging design with DTG material behavior, Pinyang ensures that hoodies arrive in market-ready condition, preserving both appearance and perceived value.

Customization Flexibility for Diverse Market Needs

DTG printing hoodies are used across multiple market segments, from independent creators to large-scale wholesalers. Pinyang Clothing supports this diversity through flexible customization options, including:

-

Custom logos and graphic placement

-

Multiple hoodie styles within one order

-

Coordinated production of hoodies, T-shirts, sweatpants, and shorts

-

Scalable quantities from 1 to 10,000+ units

This flexibility allows brands to test, refine, and expand DTG collections without changing manufacturing partners.

Project Management and Communication as Production Enablers

Seamless customization relies on accurate communication as much as technical execution. Pinyang Clothing emphasizes effective project management to align timelines, approvals, and production milestones.

Clients benefit from:

-

Structured development schedules

-

Clear sampling and production updates

-

Rapid response during design or production adjustments

This support framework is especially critical for international buyers managing cross-border supply chains and seasonal launches.

Industry Perspective: DTG Printing in Modern Apparel Manufacturing

As apparel brands prioritize personalization, rapid turnaround, and lower minimums, DTG printing continues to gain traction. Industry forecasts indicate steady growth in DTG adoption, particularly for hoodies and casualwear categories.

Manufacturers with vertically integrated DTG-ready workflows are increasingly preferred, as they reduce operational risk while maintaining creative freedom—positioning partners like Pinyang Clothing as long-term strategic manufacturers rather than transactional suppliers.

FAQ: DTG Printing Hoodie Customization

Q1: What fabric types work best for DTG hoodies?

High-cotton-content fabrics with consistent knit density deliver the best print clarity and durability.Q2: Can DTG hoodies be produced at scale?

Yes, with standardized workflows and quality controls, DTG hoodies can be produced reliably at high volumes.Q3: How is print durability ensured during shipping?

Proper curing, protective folding, and export-grade packaging prevent print damage in transit.Q4: Can DTG printing be combined with other garment styles?

Yes, DTG printing can be applied across hoodies, T-shirts, sweatpants, and coordinated apparel sets.

Conclusion

Seamless DTG hoodie customization is not achieved through printing technology alone. It requires synchronized execution across fabric sourcing, pattern making, quality control, and export packaging.

With strong vertical integration, OEM & ODM manufacturing expertise, and a commitment to uncompromising quality, Pinyang Clothing provides a reliable pathway for transforming DTG hoodie concepts into scalable, market-ready products. From single-piece prototypes to global distribution, every stage is engineered to support brand growth and long-term consistency.

https://www.ncpy.net/

Nanchang Pinyang Clothing Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.