- This topic is empty.

-

AuthorPosts

-

2025-07-22 at 6:35 pm #25606

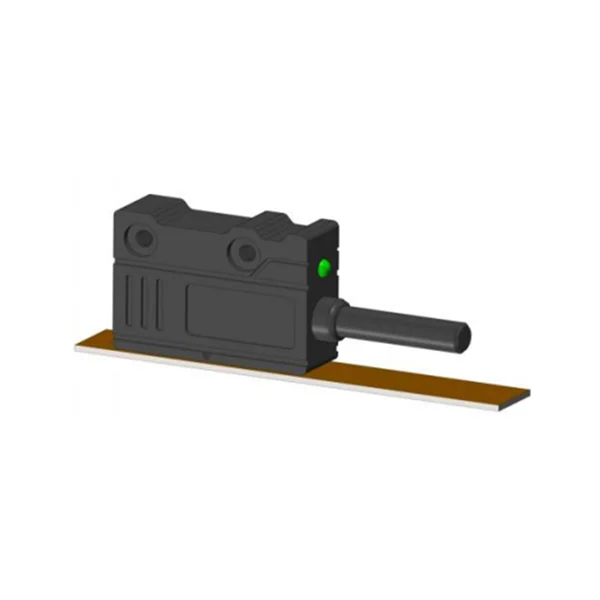

Magnetic scale linear encoders are advanced position sensing devices that convert linear or rotary displacement into an electronic signal for precise measurement. They are widely used in CNC machinery, automation equipment, industrial robotics, and motion control systems where harsh environments, space constraints, and high precision are key considerations. In this blog post, ENX Enxiao, a high precision linear scale encoder manufacturing factory, will share the performance features of magnetic scale linear encoders for sale.

1. Robust Protection Against Environmental Damage

One of the most significant challenges in industrial settings is protecting signal lines from mechanical and thermal damage caused by metal chips and hot debris generated during machining processes. Magnetic scale linear encoders address this by allowing the integration of metal sleeves to safeguard sensitive signal lines. These protective sleeves act as barriers against sharp cutting chips and high temperatures, ensuring consistent data transmission and extending the lifespan of the encoder system.

2. Simplified Design and Installation

Industrial users often prefer systems that are easy to deploy and maintain. Magnetic scale linear encoders feature a simple mechanical structure, making installation straightforward even in confined or complex machine setups. Their plug-and-play design minimizes setup time and reduces the need for specialized installation tools. Additionally, the system allows for easy switching and replacement, which significantly reduces downtime in case of maintenance or reconfiguration.

3. Efficient Signal Output and Real-Time Processing

These encoders are designed to provide accurate Index signals and support periodic real-time signal processing, which is essential for maintaining precision during high-speed operations. The output signals can be easily integrated with PLCs, motion controllers, and other digital systems, ensuring smooth communication and synchronization between machine components.

Real-time signal processing allows for quick feedback loops that are vital in dynamic environments, such as CNC tool positioning, where timing and accuracy are critical.

4. Compact Structure for Space-Constrained Installations

In modern equipment design, compactness is a valuable attribute. Magnetic scale linear encoders offer a small form factor and compact installation, allowing them to be integrated into tight spaces without compromising performance. This compact design makes them suitable for applications such as small automation modules, miniature robots, and compact actuators.

Despite their size, these encoders maintain high levels of durability and functionality, making them ideal for OEMs and system integrators seeking space-saving solutions.

5. Non-Contact Measurement Ensures Long-Term Durability

Unlike traditional contact-based encoders, magnetic scale linear encoders operate using non-contact magnetic sensing. This method eliminates physical wear and tear associated with friction-based systems, leading to longer service life and reduced maintenance requirements.

By measuring linear or rotational displacement through magnetic field variations without mechanical contact, these encoders provide high reliability and stability, even in dusty or oily environments where optical systems may fail.

6. High Precision with Resolution Up to 5 μm

Precision is a critical metric in many industrial applications. Magnetic scale linear encoders offer resolutions of up to 5 micrometers (μm), enabling accurate positioning and motion control even in applications requiring fine measurements. Such high resolution ensures optimal performance in precision assembly, semiconductor processing, and high-speed machining.

Despite operating in less-than-ideal environmental conditions, the encoder maintains its accuracy through intelligent signal interpolation and noise reduction techniques.

7. Compatible with Magnetic Rulers and Magnetic Rings

The magnetic encoder system is designed to work seamlessly with magnetic rulers (for linear applications) and magnetic rings (for rotary motion). This modular compatibility enables engineers to select the most suitable configuration for their specific use case.

The matching of encoder heads with pre-calibrated magnetic scales ensures optimized system accuracy, while also offering flexibility in encoder length and configuration. Whether used for long travel distances or precise rotary positioning, the combination enhances overall system integration.

8. Applications and Versatility

Due to their durability, accuracy, and ease of use, magnetic scale linear encoders are widely employed in:

* CNC machining centers and milling machines

* Automated assembly lines

* Robotic arms and actuators

* Semiconductor and electronics manufacturing

* Packaging and textile machinery

They are especially valued in harsh or dynamic environments, where dust, oil, vibration, and temperature fluctuations would compromise the reliability of traditional optical or capacitive encoders.

Conclusion

The magnetic scale linear encoder stands out for its robustness, precision, and user-friendly design. From non-contact sensing to real-time signal processing and high-resolution output, it meets the demands of modern industrial automation and motion control systems. Whether your application involves harsh operating conditions, tight installation spaces, or high-accuracy positioning, this encoder offers a reliable and efficient solution.

By incorporating protective features such as metal sleeves and enabling compatibility with magnetic scales and rings, it ensures both performance longevity and flexibility, making it a valuable investment for industries aiming to enhance productivity and accuracy.

http://www.enxsensors.com

ENX Enxiao -

AuthorPosts

- You must be logged in to reply to this topic.