- This topic is empty.

-

AuthorPosts

-

2025-09-09 at 4:02 pm #26050

In today’s manufacturing landscape, the demand for efficient plastic recycling solutions is at an all-time high. With increasing emphasis on sustainability, industries are turning to advanced technologies to reduce waste, cut costs, and promote a circular economy. Among these technologies, disc type PP grinders have emerged as a vital tool for processing polypropylene (PP) and other thermoplastic materials. These machines play a critical role in improving recycling efficiency across a wide range of industrial applications.

What Are Disc Type PP Grinders?

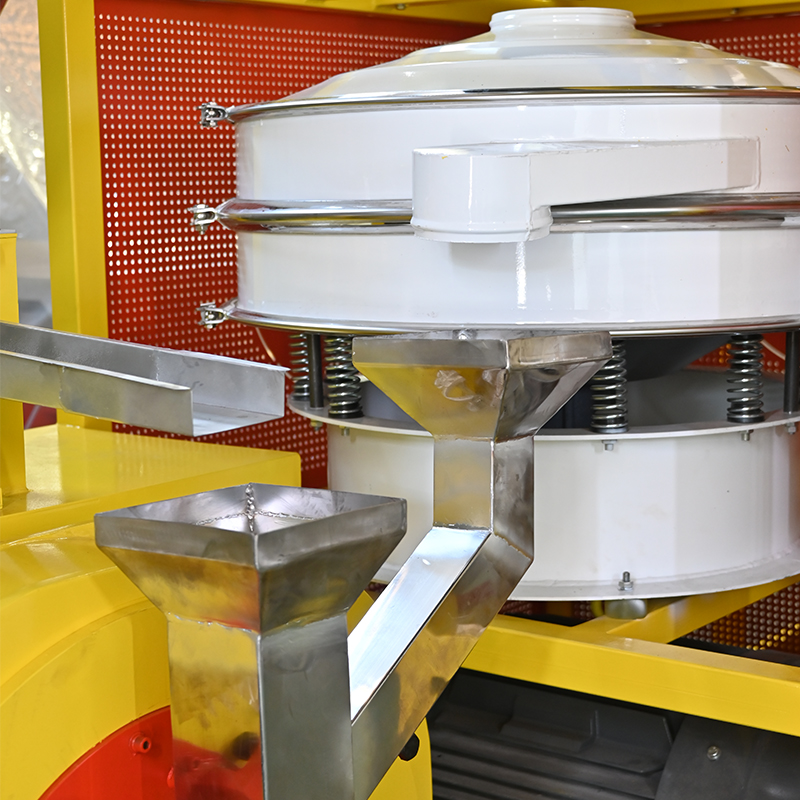

Disc type PP grinders are specialized machines designed to pulverize or grind polypropylene plastic waste into fine powder or granules, making it suitable for reuse in manufacturing processes. Unlike conventional crushing equipment, disc grinders utilize a unique disc grinding mechanism that ensures uniform particle size, minimal material loss, and improved energy efficiency.

Key Industrial Applications

1. Plastic Recycling Plants

Disc type PP grinders are widely used in plastic recycling facilities to process post-consumer and post-industrial PP waste. The fine powder produced can be reused directly in injection molding, extrusion, and blow molding processes, reducing the need for virgin materials.

2. Packaging Industry

The packaging sector, which heavily relies on PP for products such as containers, caps, and films, benefits significantly from disc grinders. By recycling defective or excess materials, manufacturers can reduce production costs while meeting sustainability goals.

3. Automotive Manufacturing

Polypropylene is commonly used in automotive interiors, bumpers, and other components. Disc type grinders help automotive manufacturers recycle offcuts, defective parts, and end-of-life plastic components, contributing to resource conservation and compliance with environmental regulations.

4. Household Goods Production

Producers of household items such as buckets, storage boxes, and kitchenware use disc PP grinders to recycle waste material generated during production, enhancing overall efficiency and reducing waste disposal costs.

5. Chemical and Industrial Applications

The ground PP powder can also be used as raw material in chemical industries or as an additive in composite materials. Disc grinders provide consistent quality, ensuring that the recycled material meets specific industrial standards.

Advantages of Disc Type PP Grinders

High Efficiency: The disc grinding system ensures faster material processing compared to traditional crushing methods.

Uniform Particle Size: Produces fine, evenly-sized powder ideal for direct reuse in production.

Energy Saving: Designed to consume less energy, leading to cost reductions in large-scale operations.

Low Maintenance: Advanced design and robust construction reduce downtime and maintenance costs.

Environmentally Friendly: Facilitates sustainable recycling and reduces dependence on virgin materials.

Songhu Xinrui Machinery: Your Reliable Partner in Plastic Grinding Solutions

When it comes to professional-grade plastic recycling machinery, Wuxi Songhu Xinrui Machinery Co., Ltd. stands out as a leading manufacturer. The company specializes in producing high-performance PE pulverizers, PVC crushers, and disc type PP grinders tailored to meet the demands of various industries.

With years of expertise, innovative engineering, and strict quality control, Wuxi Songhu Xinrui ensures its machines deliver superior grinding performance, long service life, and enhanced recycling efficiency. Whether you are operating a recycling plant or managing plastic waste in your production line, their solutions can help you maximize material recovery while reducing operational costs.

Conclusion

Disc type PP grinders have revolutionized plastic recycling by offering a fast, efficient, and eco-friendly way to process polypropylene waste. From packaging and automotive to household goods and chemical industries, their applications continue to expand, driving both economic and environmental benefits.

Choosing a reliable partner like Wuxi Songhu Xinrui Machinery Co., Ltd. ensures you gain access to top-quality equipment designed for high performance and long-term sustainability. By integrating advanced disc grinding technology into your recycling process, you are not only boosting efficiency but also contributing to a greener, more sustainable future.

http://www.songhuxr.com

Wuxi Songhu Xinrui Machinery Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.