- This topic is empty.

-

AuthorPosts

-

2025-11-07 at 6:00 pm #26578

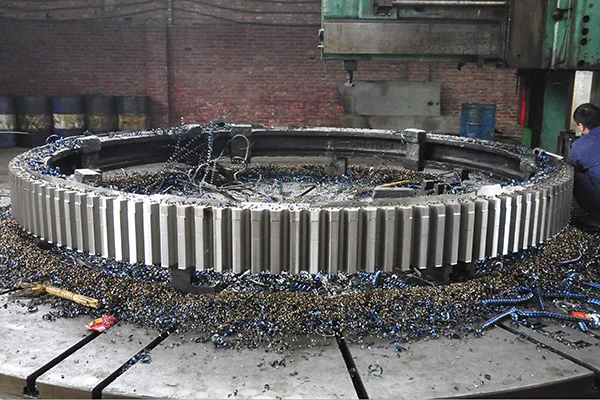

Girth gears are essential components in heavy industry, enabling the smooth rotation of cement mills, mining crushers, forging machinery, and shipbuilding equipment. A well-maintained girth gear system not only ensures operational efficiency but also significantly reduces downtime and costly repairs. Understanding proper maintenance practices and preventive measures is critical for industrial operators.

China Special Metal Group Limited (CSM) is a leading supplier of cast steel components, precision-machined products, and welded assemblies for metallurgical machinery, cement and mining machinery, building materials equipment, ceramics, forging, shipbuilding, and chemical industries. CSM’s expertise in high-quality girth gears and related components ensures long-lasting performance under demanding industrial conditions.

1. Regular Inspection and Monitoring

Routine inspections are the first line of defense against girth gear failure. Key inspection points include:

-

Tooth Wear: Examine the teeth for uneven wear, pitting, or cracks. Early detection prevents severe damage to the pinion and surrounding equipment.

-

Lubrication Status: Check oil levels, viscosity, and cleanliness. Proper lubrication minimizes friction and heat, extending gear life.

-

Alignment: Ensure the girth gear and pinion are correctly aligned. Misalignment causes uneven load distribution and accelerates wear.

-

Noise and Vibration: Unusual sounds or vibrations can indicate gear tooth damage or bearing issues, signaling the need for immediate attention.

2. Proper Lubrication Practices

Lubrication is crucial for reducing friction and wear in girth gear systems:

-

Use high-quality gear oils or grease recommended for heavy-load applications.

-

Maintain consistent lubrication intervals based on manufacturer guidelines and operating conditions.

-

Monitor for contamination from dust, water, or metal particles, which can compromise the gear surface.

-

Consider automatic lubrication systems for large or critical equipment to maintain optimal oil levels consistently.

3. Alignment and Load Management

Proper alignment between the girth gear and the pinion is vital:

-

Check alignment during installation and after any maintenance or repositioning.

-

Avoid overloading the system beyond its rated capacity, as excessive torque and uneven load distribution can cause tooth breakage and premature wear.

-

Gradually start and stop heavy machinery to reduce stress on the gear teeth and supporting bearings.

4. Cleaning and Environmental Protection

Girth gears often operate in harsh environments such as cement plants, mines, or forging facilities:

-

Remove dust, grit, and debris regularly to prevent surface abrasion.

-

Protect exposed gears from moisture and corrosive substances using coatings, shields, or covers.

-

Ensure surrounding equipment, like rollers and bearings, is also clean and properly maintained to avoid secondary damage.

5. Regular Maintenance Schedule

A proactive maintenance plan can significantly extend the lifespan of girth gear systems:

-

Monthly Checks: Visual inspection of gear teeth, lubrication status, and noise monitoring.

-

Quarterly Maintenance: Alignment verification, oil sampling, and vibration analysis.

-

Annual Maintenance: Comprehensive inspection including gear tooth measurement, potential regrinding, and bearing replacement if necessary.

6. Partnering with a Trusted Supplier

Selecting high-quality components from a reliable manufacturer like China Special Metal Group Limited (CSM) ensures that your girth gears withstand demanding industrial environments:

-

CSM provides durable cast steel gears, precision machining, and welded assemblies tailored to specific industrial applications.

-

Their products are designed to resist wear, fatigue, and high torque loads, reducing the frequency of repairs and downtime.

-

Working with a trusted supplier allows access to technical support and guidance for installation, maintenance, and operational optimization.

Conclusion

Maintaining a girth gear system is more than routine cleaning—it requires inspection, proper lubrication, alignment, load management, and environmental protection. By following these best practices, industrial operators can maximize equipment efficiency, prevent costly downtime, and extend the lifespan of their girth gear systems.

With China Special Metal Group Limited (CSM) as your partner, you gain access to high-quality cast steel components, precision-engineered girth gears, and expert support, ensuring your machinery operates reliably under the most demanding conditions.

http://www.special-metal.com

China Special Metal Group Limited (CSM) -

-

AuthorPosts

- You must be logged in to reply to this topic.