- This topic is empty.

-

AuthorPosts

-

2025-07-21 at 10:30 am #25583

Grinding wheels are essential tools in manufacturing and metalworking industries, enabling precise cutting, shaping, and finishing of materials. However, like any tool, grinding wheels require proper maintenance to ensure optimal performance and a longer service life. Neglecting maintenance can lead to poor grinding quality, increased downtime, and higher operational costs.

Signi Industrial (Shanghai) Co., Ltd, a leading company specializing in the research, production, and sales of abrasives and diamond products, offers a wide range of grinding wheels including fiber-reinforced resin cutting discs, ultra-thin wheels, cup-shaped wheels, and flexible grinding wheels. With over 1,000 product varieties exported to more than 40 countries, Signi Industrial emphasizes the importance of grinding wheel care to maximize efficiency.

Here are some expert tips to help you maintain your grinding wheels effectively:

1. Regular Inspection and Cleaning

Inspect your grinding wheels frequently for cracks, chips, or wear. Damaged wheels can compromise safety and grinding precision. Use a brush or compressed air to clean the wheel’s surface and remove any debris, dust, or buildup that can affect cutting performance.

2. Proper Dressing of Grinding Wheels

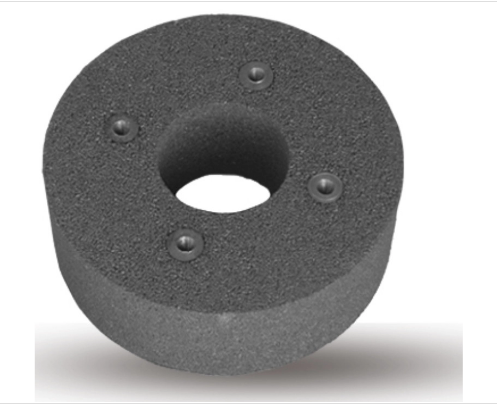

Dressing is the process of removing clogged or worn abrasive grains to restore the wheel’s cutting ability and shape. Using the correct dressing tools and techniques helps maintain wheel balance and surface finish quality. Signi Industrial’s grinding wheels, including ultra-thin and cup-shaped varieties, are designed for easy dressing, ensuring smooth operation.

3. Use the Right Wheel for the Material

Different materials require specific types of grinding wheels. For instance, fiber-reinforced resin cutting discs are excellent for cutting metals, while diamond wheels are preferred for hard, brittle materials like ceramics. Using the right wheel reduces wear and improves grinding results.

4. Maintain Optimal Speed and Pressure

Operating the grinding wheel at the recommended speed prevents overheating and premature wear. Similarly, applying consistent and appropriate pressure avoids uneven grinding and wheel damage. Overloading the wheel can lead to fractures, while underloading reduces efficiency.

5. Store Grinding Wheels Properly

Store grinding wheels in a dry, temperature-controlled environment away from moisture and contaminants. Avoid stacking wheels horizontally to prevent deformation. Signi Industrial’s product packaging ensures safe storage and transport, preserving wheel integrity.

6. Follow Manufacturer Guidelines

Always adhere to the manufacturer’s specifications for wheel usage, speed limits, and maintenance procedures. Signi Industrial provides detailed technical support and product information to help users maximize grinding wheel performance.

Conclusion

Proper maintenance of grinding wheels not only enhances safety but also significantly extends their service life and grinding efficiency. By following regular inspection, correct dressing, and appropriate usage practices, you can reduce operational costs and improve product quality.

With a diverse product range and commitment to quality, Signi Industrial (Shanghai) Co., Ltd remains a trusted partner in abrasive technology, helping industries worldwide achieve precision and durability in grinding applications.

http://www.shanghai-signi.com

Signi Industrial (Shanghai) Co., Ltd -

AuthorPosts

- You must be logged in to reply to this topic.