- This topic is empty.

-

AuthorPosts

-

2026-01-05 at 2:32 pm #27302

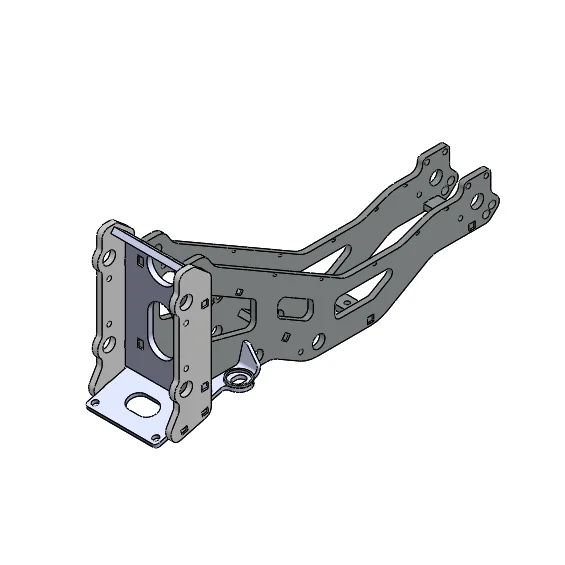

In modern industrial manufacturing, support brackets are essential components that ensure structural stability and safety across a wide range of applications—from construction machinery and agricultural equipment to special vehicles, energy systems, and automotive components. For manufacturers, achieving high-quality, precise, and cost-effective support bracket production requires a streamlined processing service that covers the entire workflow, from design to assembly.

Hengli, as a modern processing enterprise specializing in the integration of the metal supply chain, offers comprehensive support bracket processing services that meet these demands, combining advanced machinery with extensive industry expertise.

1. Initial Design and Engineering

Every successful support bracket starts with precise design. Hengli works closely with clients to understand functional requirements, load capacities, and environmental conditions to produce optimized designs.

Key Considerations:

-

Material selection to balance strength and weight.

-

Structural design to withstand mechanical stress.

-

Compatibility with assembly and mounting requirements.

Advanced software and engineering tools are used to simulate performance and identify potential issues before production, ensuring efficiency and reducing costly errors.

2. Cutting and Shaping: Laser, Flame, and Plasma

The first physical step in support bracket production is accurate cutting and shaping. Hengli utilizes laser cutting, flame cutting, and plasma cutting depending on material thickness, shape complexity, and precision requirements.

Practical Advantages:

-

Laser cutting delivers high precision and smooth edges for complex bracket geometries.

-

Flame and plasma cutting are ideal for thicker or larger steel plates used in construction machinery or heavy vehicles.

-

Minimizing material waste while maintaining structural integrity.

3. Bending, Forming, and Punching

Once cut, brackets often require additional shaping. Hengli’s advanced bending, forming, and punching machines ensure that components meet exact specifications.

Best Practices:

-

Use CNC-controlled bending to maintain consistent angles.

-

Integrate forming and punching steps in sequence to reduce handling and deformation.

-

Customize hole placements for mounting, welding, or assembly.

This stage ensures that each bracket is production-ready while maintaining high dimensional accuracy.

4. Welding and Robotic Assembly

Welding is a critical step for multi-part support brackets. Hengli employs both manual and robotic welding to achieve strong, consistent joints while minimizing distortion.

Highlights:

-

Robot welding offers high precision and repeatability for large production volumes.

-

Weld quality is strictly monitored to meet industry standards for construction, automotive, and energy applications.

-

Optional finishing techniques, including grinding and polishing, ensure smooth surfaces for assembly.

5. Surface Treatment and Coating

To enhance durability, corrosion resistance, and aesthetics, support brackets often undergo surface treatments such as powder coating, painting, or galvanizing. Hengli’s advanced coating lines ensure uniform coverage, long-lasting protection, and compliance with industrial specifications.

Practical Tip:

-

Match surface treatment with the application environment (outdoor machinery, automotive exposure, energy installations) to maximize longevity.

6. Quality Control and Inspection

Every support bracket produced by Hengli undergoes rigorous quality control, including:

-

Dimensional checks for exact tolerances.

-

Visual inspection for weld and surface quality.

-

Load and stress testing for critical structural components.

These inspections ensure that each bracket not only meets design specifications but also adheres to industry safety standards.

7. Efficient Assembly and Delivery

Finally, support brackets are ready for assembly. Hengli’s integrated workflow—from cutting and shaping to finishing and inspection—reduces lead time and ensures that brackets arrive on-site ready for installation.

Advantages for Customers:

-

Faster project turnaround.

-

Reduced risk of errors during installation.

-

Consistent quality across large production batches.

Conclusion

A high-quality support bracket processing service requires more than just cutting and welding—it requires a full-service, integrated workflow that spans design, fabrication, finishing, and inspection. Hengli’s advanced capabilities, including CNC machining, laser cutting, robotic welding, and comprehensive surface treatments, ensure that support brackets meet the demanding standards of construction machinery, agricultural equipment, special vehicles, energy systems, and automotive components.

By partnering with Hengli, manufacturers gain precision, reliability, and efficiency from design to assembly, ensuring their projects are completed on time, within budget, and to the highest quality standards.

http://www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.