- This topic is empty.

-

AuthorPosts

-

2025-12-09 at 4:19 pm #26943

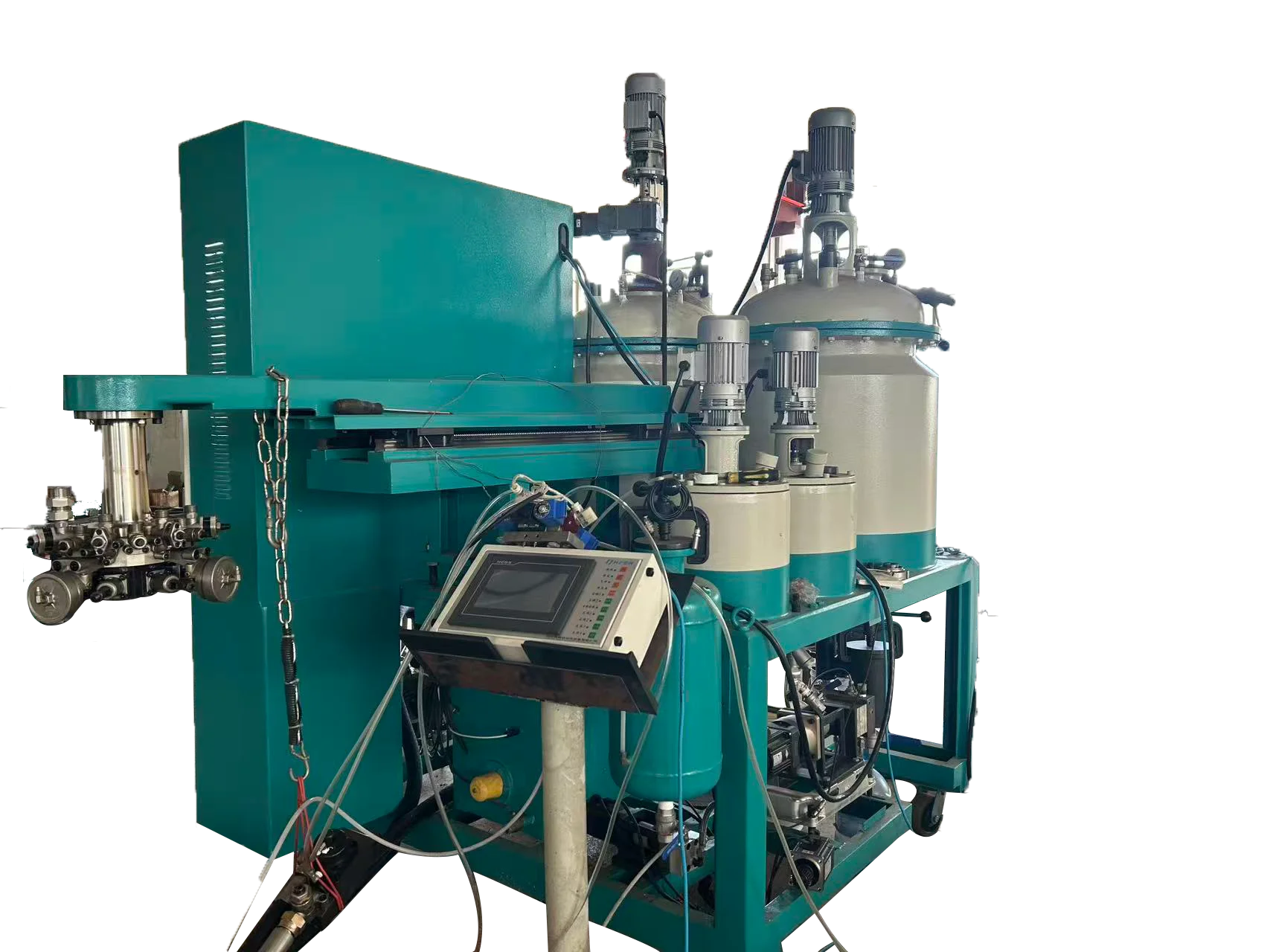

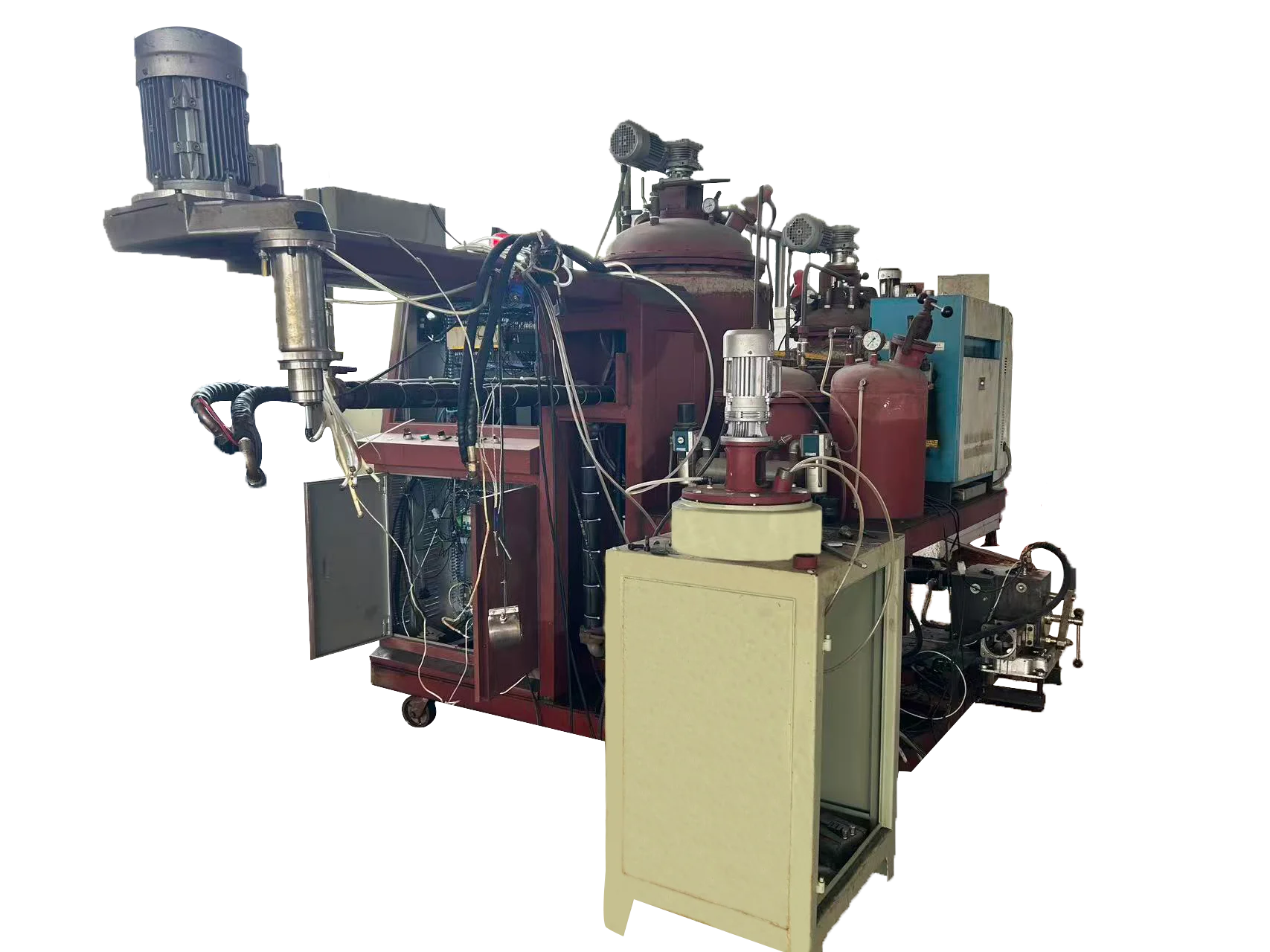

Elastomer forming machines have become indispensable in today’s manufacturing world. Their ability to transform flexible polymers—especially polyurethane—into high-performance components allows industries to achieve greater durability, precision, and reliability in their products. As technology advances, manufacturers increasingly rely on elastomer equipment to meet market demands for stronger, more resilient, and highly customized parts.

As a specialized manufacturer of polyurethane production and processing equipment and system solutions, Haifeng provides advanced, efficient, and stable machinery to global industries seeking superior elastomer molding performance. With strong technical expertise and a commitment to quality engineering, Haifeng delivers equipment that enhances productivity, improves product consistency, and supports large-scale industrial growth.

Understanding the Capabilities of Elastomer Forming Machines

Elastomer forming machines are engineered to process polyurethane and other elastic materials into complex shapes with exceptional physical properties. These machines are equipped with:

-

High-precision metering systems for accurate chemical ratio control

-

Efficient mixing heads that ensure uniform material blending

-

Stable temperature regulation to guarantee consistent curing

-

Robust injection units capable of producing dense, durable components

Such equipment enables manufacturers to create elastomer parts with excellent elasticity, superior wear resistance, high structural integrity, and long-term performance stability. These characteristics make elastomer components ideal for demanding environments where reliability is critical.

Applications in Automotive Manufacturing

The automotive sector relies heavily on elastomer components for safety, comfort, and performance. Elastomer forming machines are widely used to produce:

-

Suspension bushings

-

Engine mounts

-

Vibration dampers

-

Gaskets and seal rings

-

Noise-reduction components

These parts require remarkable fatigue resistance, strong impact absorption, and precise dimensional accuracy, all of which can be achieved with Haifeng’s high-quality polyurethane processing equipment. Automotive manufacturers benefit from consistent output, customizable material properties, and reduced production downtime.

Importance in Hydraulic and Pneumatic Sealing Systems

Hydraulic and pneumatic machinery depends on high-performance seals capable of withstanding intense pressure, variable temperatures, and continuous mechanical motion. Elastomer forming machines are essential for producing:

-

O-rings

-

Rod and piston seals

-

Wear rings

-

Customized hydraulic gaskets

These sealing components must be dense, chemically resistant, and compression-resilient to ensure leak-free operation. Haifeng’s elastomer equipment supports the creation of sophisticated seals with smooth surfaces, uniform hardness, and exceptional long-term durability.

Uses in Footwear Production and Synthetic Materials

In the footwear industry, elastomers contribute to comfort, flexibility, and lightweight design. Elastomer forming machines enable the production of:

-

Polyurethane midsoles

-

Shock-absorbing insoles

-

Cushioning pads

-

Fashionable, durable upper materials

Synthetic leather materials also benefit from elastomer processing, resulting in surfaces with smooth texture, excellent abrasion resistance, and high flexibility. Haifeng’s machines ensure stable quality, allowing footwear and synthetic material manufacturers to achieve consistent, premium-grade products.

Role in Electronics, Electrical Applications, and General Industrial Use

Elastomer components are crucial for protecting electronic devices and improving mechanical performance. Elastomer forming machines support the creation of:

-

Vibration-damping elements

-

Protective housings

-

Flexible insulation layers

-

Cable coatings

-

Shock-absorbing components

These parts are valued for their thermal stability, electrical insulation, and structural resilience. Beyond electronics, elastomers are used throughout the transportation industry, chemical research laboratories, and industrial equipment manufacturing, where they help reduce noise, absorb shocks, and protect sensitive components.

Haifeng’s machinery serves these sectors with versatile processing capabilities, steady operational performance, and customizable system configurations tailored to specialized production needs.

Conclusion

Elastomer forming machines have transformed industrial production by enabling the creation of strong, elastic, and durable components essential to modern engineering. From automotive parts to hydraulic seals, footwear materials, and electronic protection systems, elastomer equipment supports industries with unmatched reliability and flexibility.

As a trusted polyurethane equipment and system manufacturer, Haifeng continues to empower manufacturers worldwide with innovative, high-precision, and energy-efficient machinery. By choosing advanced elastomer forming solutions, companies can elevate product quality, streamline production, and maintain a competitive edge in a rapidly evolving market.

How to Choose a High-Quality Low-Pressure Foaming Machine: An Expert Guide

http://www.haifeng-automation.cn

Haifeng -

-

AuthorPosts

- You must be logged in to reply to this topic.