- This topic is empty.

-

AuthorPosts

-

2026-02-02 at 5:23 pm #27563

High pressure foaming machines play a vital role in modern industrial manufacturing, enabling efficient, precise, and consistent production of polyurethane (PU) and other foam materials. As industries continue to demand higher product quality, automation, and energy efficiency, these machines have become essential equipment across sectors such as automotive manufacturing, construction, and household appliances.

This article explores the core applications of high pressure foaming machines, their technical advantages, and how experienced manufacturers like Haifeng Automation Equipment Co., Ltd support global industries with advanced polyurethane processing solutions.

What Are High Pressure Foaming Machines?

High pressure foaming machines are industrial systems designed to accurately meter, mix, and inject foam-forming materials—typically polyol and isocyanate—under high pressure. The high-pressure mixing process ensures excellent material homogeneity, rapid chemical reaction, and stable foam quality.

Compared with low pressure systems, high pressure foaming machines offer:

-

More uniform foam structure

-

Higher production efficiency

-

Better control of density and physical properties

-

Reduced material waste

These advantages make them ideal for large-scale, high-quality foam production in demanding industrial environments.

Key Advantages of High Pressure Foaming Technology

High pressure foaming machines are widely adopted because of several critical technical benefits:

-

Precise Metering and Mixing: Ensures accurate material ratios and consistent foam quality.

-

High Automation Level: Digital control systems allow automated operation, reducing labor costs.

-

High Output and Stability: Suitable for continuous industrial production.

-

Versatility: Capable of producing rigid, flexible, and semi-rigid foams for different applications.

These features help manufacturers improve productivity while maintaining strict quality standards.

Automotive Industry Applications

Interior Components and Comfort Systems

In the automotive industry, high pressure foaming machines are extensively used to manufacture interior foam components, including:

-

Car seats and seat cushions

-

Headrests and armrests

-

Door panels and dashboard padding

-

Steering wheel foam

These components require consistent density, durability, and comfort. High pressure foaming technology ensures uniform foam distribution and strong bonding with substrates, enhancing long-term performance and passenger comfort.

Structural and Acoustic Insulation

High pressure polyurethane foam is also applied in vehicle cavities to improve:

-

Thermal insulation

-

Sound absorption

-

Vibration reduction

Accurate foam injection helps optimize vehicle weight while improving energy efficiency and driving comfort.

Construction and Building Applications

Thermal Insulation Panels

In the construction industry, high pressure foaming machines are widely used to produce insulation materials such as:

-

Sandwich panels

-

Wall and roof insulation boards

-

Cold storage and refrigerated panels

Polyurethane foam offers excellent thermal insulation and low thermal conductivity, helping buildings meet energy-saving and sustainability requirements.

Spray Foam and Modular Construction

High pressure systems are also applied in:

-

Spray foam insulation for walls and roofs

-

Prefabricated and modular building components

-

Structural foam cores for lightweight construction

Precise pressure and temperature control ensure complete cavity filling and strong bonding, reducing heat loss and improving building durability.

Appliance Manufacturing Applications

Refrigerator and Freezer Insulation

Household appliances such as refrigerators and freezers rely heavily on high-quality insulation. High pressure foaming machines inject PU foam into appliance cavities to:

-

Improve thermal efficiency

-

Reduce energy consumption

-

Enhance temperature stability

This helps appliance manufacturers comply with increasingly strict energy efficiency regulations.

Structural and Noise-Reduction Components

Foam materials are also used in appliances for structural support, vibration damping, and noise reduction. High pressure foaming technology ensures consistent foam properties, contributing to quieter and more reliable products.

Why Choose Haifeng High Pressure Foaming Machines?

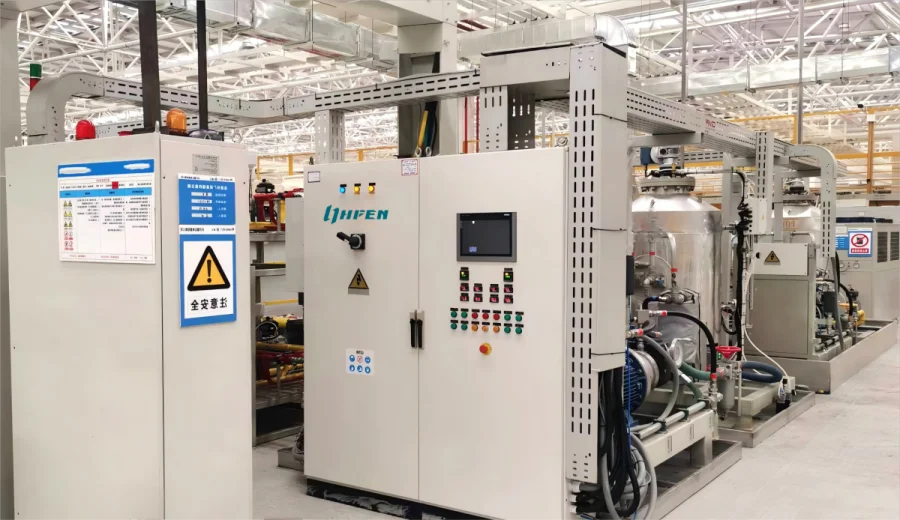

Haifeng Automation Equipment Co., Ltd is a professional manufacturer specializing in polyurethane processing and automation equipment. Established in 2001, Haifeng has extensive experience in developing high pressure foaming machines and customized automation solutions for global industries.

According to the company profile, Haifeng’s product portfolio includes:

-

High pressure and low pressure foaming machines

-

Polyurethane elastomer processing systems

-

Automated spraying and pouring equipment

Haifeng solutions are widely used in automotive, construction, appliance, footwear, and transportation industries. The company focuses on innovation, reliability, and intelligent control systems to help customers achieve efficient and stable production.

Frequently Asked Questions (FAQs)

Q1: What is the difference between high pressure and low pressure foaming machines?

High pressure foaming machines use higher injection pressure and advanced mixing heads to achieve better material mixing, faster reaction time, and more consistent foam quality.Q2: Are high pressure foaming machines suitable for both rigid and flexible foam?

Yes. By adjusting process parameters, high pressure systems can produce rigid, flexible, or semi-rigid polyurethane foams for different applications.Q3: Can high pressure foaming machines be customized for specific industries?

Absolutely. Many manufacturers, including Haifeng, offer customized solutions based on materials, molds, production capacity, and automation requirements.Q4: Which industries benefit most from high pressure foaming machines?

Automotive, construction, appliance manufacturing, furniture, packaging, and insulation industries benefit greatly from high pressure foaming technology.Q5: How do I choose the right high pressure foaming machine?

-

-

AuthorPosts

- You must be logged in to reply to this topic.