- This topic is empty.

-

AuthorPosts

-

2025-09-15 at 6:16 pm #26138

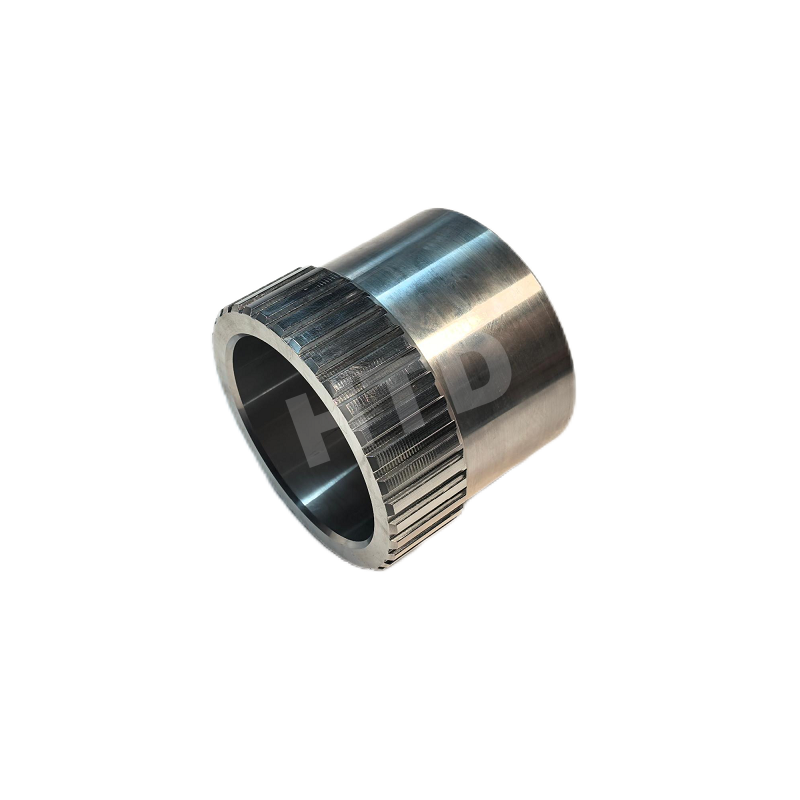

In modern mechanical systems, precision and reliability are crucial for optimal performance. One key component that directly affects efficiency and durability is the AT10 pulley. Often used in timing belt systems, AT10 pulleys ensure accurate power transmission and consistent mechanical operation. Choosing the right pulley can reduce wear, prevent system failures, and extend the life of your machinery.

Hetuoda Machinery Manufacturing specializes in producing high-precision transmission components, including timing pulleys, rack gears, tensioner pulleys, gears, and various machined parts. They also provide OEM services, offering customized solutions to meet the unique requirements of diverse industrial applications.

What Is an AT10 Pulley?

An AT10 pulley is a type of timing belt pulley designed with a 10 mm pitch, commonly used in synchronous belt drives. These pulleys maintain precise alignment between the belt and the mechanical components, ensuring smooth and reliable power transmission in machinery ranging from conveyors to automated manufacturing equipment.

Key Features of AT10 Pulleys:

-

High Precision – Ensures minimal backlash and accurate belt positioning.

-

Durable Construction – Typically made from aluminum, steel, or other high-strength alloys to withstand industrial loads.

-

Compatibility – Designed to fit AT10 timing belts for various applications.

-

Customizable Options – Available in multiple sizes, tooth profiles, and materials to match specific machinery requirements.

Advantages of Using AT10 Pulleys

1. Improved Mechanical Efficiency

AT10 pulleys provide precise power transmission with minimal slippage, which improves the efficiency of your machinery and reduces energy losses.

2. Extended Belt and Component Life

By ensuring proper alignment and tension, AT10 pulleys reduce wear on belts and other transmission components, minimizing maintenance costs and downtime.

3. High Load Capacity

High-quality AT10 pulleys can handle significant torque and load requirements, making them suitable for demanding industrial applications.

4. Versatility

These pulleys are used in automated production lines, packaging machines, CNC equipment, conveyors, and other precision machinery, offering a wide range of industrial applications.

5. Ease of Installation and Replacement

Standardized dimensions and precise manufacturing allow for quick installation and easy replacement, reducing production downtime.

Factors to Consider When Choosing an AT10 Pulley

-

Pulley Diameter and Tooth Count – Determines the belt speed and torque transmission.

-

Material Selection – Steel pulleys offer high strength; aluminum provides lighter weight and corrosion resistance.

-

Bore Size and Keyway Compatibility – Ensure proper fit with your shaft and mechanical setup.

-

Load Requirements – Consider torque and load to select a pulley that can handle your application demands.

-

Manufacturer Reliability – Choose a trusted supplier for high-precision pulleys to ensure quality and longevity.

Why Choose Hetuoda Machinery Manufacturing?

Hetuoda Machinery Manufacturing is a trusted partner for high-precision transmission components. Their key advantages include:

-

Extensive Product Range: Timing pulleys, rack gears, tensioner pulleys, gears, and custom machined parts.

-

OEM Services: Customized components tailored to specific machinery requirements.

-

High-Quality Manufacturing: Precision engineering and strict quality control ensure consistent performance.

-

Industry Experience: Expertise in industrial machinery, ensuring reliable solutions for complex applications.

With Hetuoda’s AT10 pulleys, companies can optimize machinery performance, reduce maintenance costs, and achieve long-term reliability in their industrial operations.

Conclusion

Selecting the right AT10 pulley is critical for ensuring the efficiency, precision, and durability of your machinery. By considering factors like size, material, load capacity, and compatibility, businesses can make informed decisions that enhance performance and reduce downtime. With a trusted supplier like Hetuoda Machinery Manufacturing, you gain access to high-quality, precision-engineered pulleys and transmission components, backed by professional OEM services to meet the unique demands of modern industrial applications.

http://www.cdepulley.com

Suzhou Hetuoda Machinery Manufacturing Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.