- This topic is empty.

-

AuthorPosts

-

2026-02-02 at 5:24 pm #27565

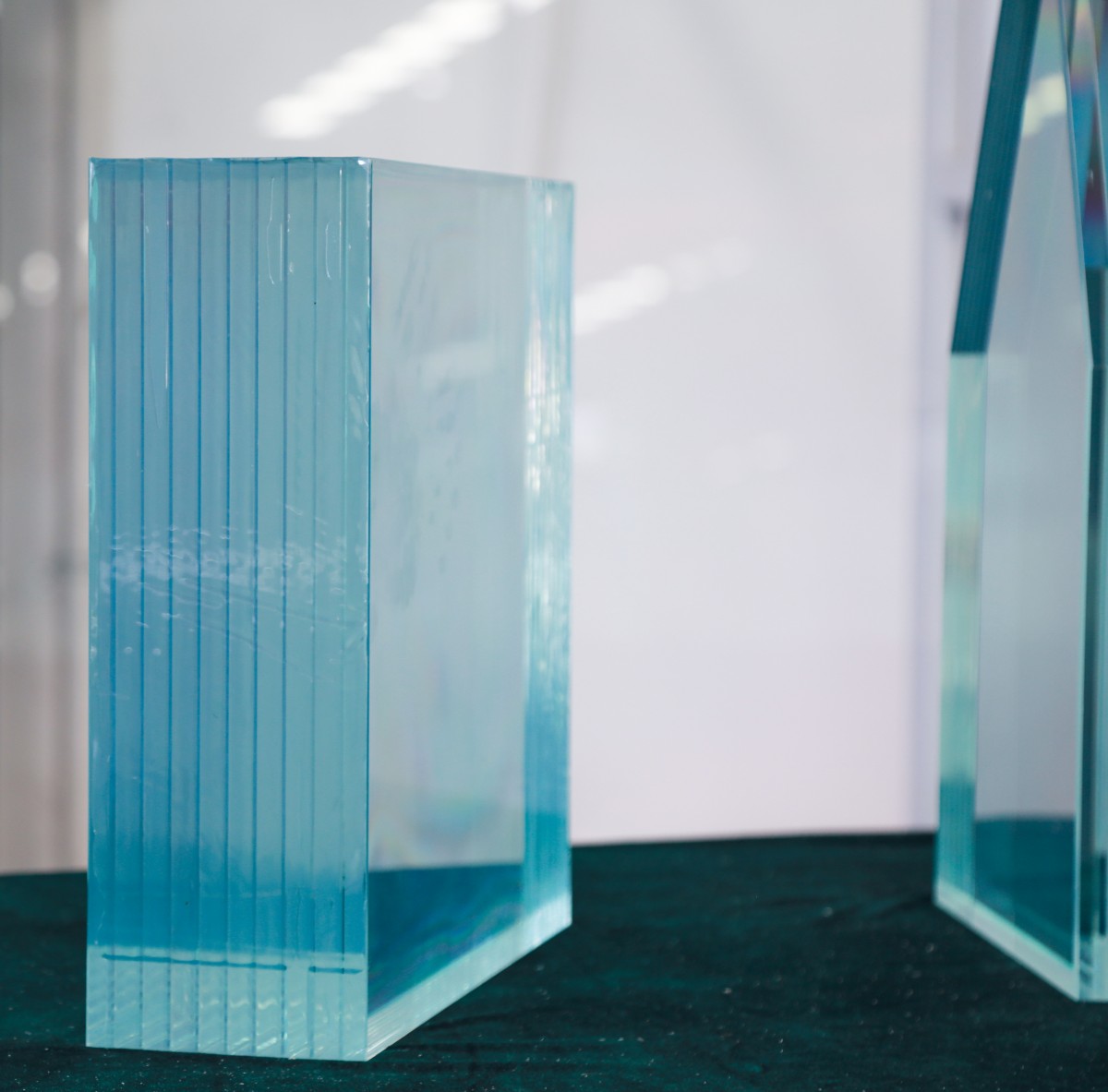

In today’s global construction market, architectural projects demand glass solutions that meet strict safety standards, structural performance requirements, and long-term durability expectations. Laminated glass has become a core material choice for commercial buildings, infrastructure projects, and high-end developments, particularly where safety glazing and engineered performance are essential.

As a professional laminated glass manufacturer, Henan Zhongbo Glass Co., Ltd. provides custom-engineered laminated glass solutions for windows, facades, skylights, and interior architectural applications, supporting overseas engineering projects from design consultation to stable production.

Why Laminated Glass Is Preferred in Engineering and Construction Projects

From an engineering and procurement perspective, laminated glass offers predictable performance and regulatory compliance, including:

-

Safety glazing compliance for overhead and high-risk areas

-

Structural integrity after breakage

-

Acoustic performance for commercial buildings

-

UV resistance for long-term interior protection

-

Compatibility with curtain wall and IGU systems

These characteristics make laminated glass suitable for specification-driven projects where material reliability is critical.

Laminated Glass Applications in Architectural Windows

For residential towers, hotels, hospitals, and office buildings, laminated glass windows provide:

-

Enhanced impact resistance and occupant safety

-

Improved acoustic insulation in urban environments

-

UV filtering to protect interior materials

-

Stable performance under wind and temperature variation

From a manufacturing standpoint, window laminated glass can be produced in multiple thickness combinations and interlayer types, allowing project-specific optimization without overdesign.

Facade and Curtain Wall Applications

Laminated glass is widely specified in modern curtain wall systems due to its structural reliability and post-breakage safety. Typical applications include:

-

Unitized and semi-unitized curtain walls

-

Structural glazing and point-fixed systems

-

High-rise commercial and mixed-use buildings

With advanced interlayers such as SGP, laminated glass supports larger panel sizes and higher design loads, while maintaining optical clarity and long-term durability.

Skylights and Overhead Glazing Systems

For overhead installations, laminated glass is often a mandatory safety requirement. In skylights, atriums, and roof glazing, laminated glass:

-

Prevents falling glass after breakage

-

Maintains panel integrity under thermal stress

-

Provides high light transmission with UV protection

-

Complies with international safety glazing standards

Manufacturers must ensure consistent lamination quality and environmental resistance for these applications.

Interior Architectural Glass Applications

In interior environments, laminated glass supports both functional performance and architectural aesthetics, commonly used for:

-

Glass partitions and office systems

-

Stair and balcony railings

-

Glass floors and walkways

-

Decorative and acoustic panels

Customization options—such as colored interlayers, printed patterns, and frosted finishes—allow laminated glass to integrate seamlessly into interior design concepts.

Key Performance Factors Considered by Engineers and Buyers

When specifying laminated glass for international projects, engineering teams typically evaluate:

-

l Glass thickness and interlayer composition

-

l Acoustic and security performance

-

l Environmental durability (UV, humidity, temperature)

-

l Compatibility with framing and installation systems

-

l Manufacturing consistency and quality assurance

Working directly with an experienced manufacturer simplifies technical coordination and specification alignment.

Manufacturing Capabilities of Henan Zhongbo Glass Co., Ltd.

As a specialized architectural glass manufacturer, Henan Zhongbo Glass Co., Ltd. offers:

-

Custom laminated glass configurations (PVB, SGP, EVA)

-

Stable optical quality and uniform bonding

-

Support for large-format and project-based production

-

Quality control aligned with international building standards

The company works closely with overseas contractors, facade companies, and project developers to deliver reliable laminated glass solutions for diverse architectural applications.

FAQ (For Engineering & Procurement Teams)

Q1: Can laminated glass be customized to meet project specifications?

Yes. Thickness, interlayer type, size, and performance can be customized based on design and safety requirements.Q2: Is laminated glass suitable for large curtain wall panels?

With proper interlayer selection, laminated glass is suitable for large-format facade systems.Q3: How does laminated glass improve post-breakage safety?

The interlayer holds broken glass fragments together, maintaining panel integrity.Q4: Can laminated glass meet international building codes?

Manufactured laminated glass can be designed to comply with widely recognized safety and architectural standards.Q5: Does the manufacturer provide technical support?

Experienced manufacturers offer technical consultation for material selection and application guidance.Conclusion: Reliable Laminated Glass Solutions for Global Projects

For modern architectural and infrastructure projects, laminated glass delivers safety, performance consistency, and design flexibility across windows, facades, skylights, and interior applications.

By partnering with an experienced manufacturer such as Henan Zhongbo Glass Co., Ltd., engineering teams and overseas buyers gain access to customized laminated glass solutions, stable production capacity, and professional technical support, ensuring project success from design to installation.

A Complete Guide to Oversized Architectural Glass in Modern Buildings

http://www.hncentralglass.com

Henan Zhongbo Glass Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.