- This topic is empty.

-

AuthorPosts

-

2025-08-11 at 2:00 pm #25760

Driven by the wave of Industry 4.0, robotic automated assembly technology has become a crucial component of intelligent manufacturing, particularly in high-precision, highly complex mechanical transmission systems. Planetary gears, as core components with compact structure, high transmission efficiency, and strong load-bearing capacity, are widely used in automobiles, electric motors, aerospace, and various industrial equipment. However, robotic assembly of planetary gears faces numerous challenges, placing extremely high demands on the equipment's precision, force control capabilities, and flexibility.

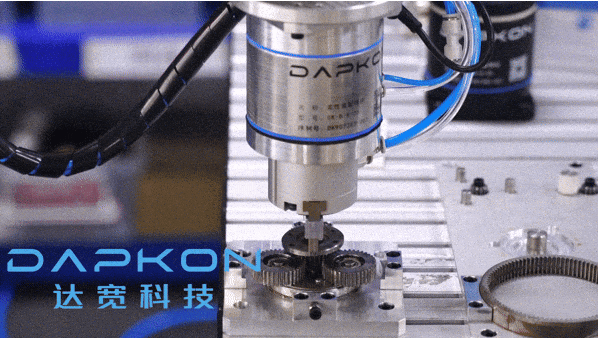

To address these difficulties, Dapkon has developed an industry-leading flexible robotic force-controlled assembly solution, providing strong technical support for high-quality and efficient automated assembly of planetary gears. This article will comprehensively analyze the application scenarios, challenges, technical advantages, and future development prospects of this technology.

1. Typical Application Scenarios for Robotic Assembly of Planetary Gears

1.1 Automotive Manufacturing Industry

In the automotive industry, planetary gear systems are a core component of automatic transmissions. Through the combination of different gears, smooth gear shifting and power transmission are achieved. When assembling these precision gears, robots must cope with extremely small tolerances, complex tooth profiles, and strict assembly sequence requirements, while also avoiding the impact of human intervention on consistency. Furthermore, differential assembly relies on multi-gear systems to compensate for wheel speed differences during cornering, reducing tire wear and enhancing handling. Robotic assembly of planetary gear systems not only improves production efficiency but also contributes to the overall quality of transmissions and differentials.

1.2 Electric Motor and Engine Manufacturing

Modern electric vehicles, power tools, and traditional internal combustion engine equipment utilize a large number of planetary gears to drive auxiliary components such as pumps, fans, and generators. The precise fit of planetary gears directly impacts the smooth operation and lifespan of the equipment. Flexible force-controlled robotic assembly systems ensure precise meshing and uniform force distribution of each gear, thereby improving overall efficiency and reliability.

1.3 Aerospace

Planetary gears are used for power conversion in aircraft propulsion systems and aircraft attitude control systems, and are a critical component for flight safety. The aerospace industry places extreme demands on component reliability and precision; any assembly error can lead to system failure. Dapkon's robotic force control technology meets these high standards, enabling intelligent, zero-defect assembly of spacecraft. 1.4 High-End Industrial Equipment

Multi-stage planetary gear systems are commonly used in transmission systems ranging from CNC machine tools and compressors to intelligent robots. These devices have extremely high requirements for transmission efficiency, response speed, and operating noise, relying on precise gear assembly. The use of robotic automated assembly technology can ensure highly consistent part assembly and excellent operating performance.

2. Major Technical Difficulties in Planetary Gear Assembly

Although robotic technology has been widely used in the manufacturing field, robotic assembly of planetary gears still faces multiple challenges:

2.1 Extremely High Precision Requirements

The meshing characteristics of planetary gear structures dictate extremely low tolerance for assembly errors. Even slight deviations can cause increased operating resistance, meshing noise, and even gear damage. Traditional rigid robots struggle to meet this high-precision docking requirement.

2.2 Complex Multi-Axis Dynamic Structure

A planetary gear system consists of a central sun gear, multiple planetary gears, and an annular ring gear. The planetary gears not only rotate on their own axis but also orbit around the sun gear, requiring extremely precise mounting positions and meshing angles. In particular, the complex distribution of the axes in the planetary carrier structure and the frequent spatial changes make the assembly process highly dynamic. 2.3 Diverse Tooth Profiles and Difficulty in Gripping

As gear manufacturing progresses towards higher efficiency and lower noise levels, more and more designs are adopting complex structures such as helical gears and variable-module gear profiles. This places higher demands on robot fixture design, visual recognition systems, and path planning algorithms.

2.4 Uncertainty and Difficulty in Contact Detection

Traditional robotic assembly lacks the ability to sense contact status, making it impossible to determine whether parts are properly aligned or if contact is too tight. This can easily lead to forced insertion, meshing damage, or assembly failure.

3. Core Advantages of the Dapkon Force Control System in Assembly

Facing these challenges, the Dapkon flexible robot force control system demonstrates the following significant advantages:

3.1 Precise Force Feedback Control

By integrating a highly sensitive six-dimensional force control sensor, the system can monitor the force applied to the robot end-piece in real time during assembly. If it detects that the assembly force exceeds the set range, the system immediately provides feedback and adjusts the operating path to avoid damage caused by forced insertion. This is particularly important for high-precision planetary gear meshing assembly. 3.2 Achieving Smooth Assembly and Automatic Error Correction

Traditional industrial robots rely solely on position control, making them unable to cope with even the slightest deviations in parts. The Dapkon system, however, incorporates a force-position hybrid control algorithm. When faced with problems like misalignment and tilted insertion, it dynamically adjusts its posture to achieve automatic alignment, significantly improving assembly success rates.

3.3 Improving Assembly Stability and Yield

By identifying contact states and determining force values during the assembly process, the system automatically adapts to the assembly characteristics of various parts, significantly reducing assembly errors and thus improving overall yield.

3.4 High Adaptability to Meet Diverse Working Conditions

The Dapkon force control system offers strong adaptability to the diverse sizes, structures, and materials of planetary gears, making it suitable for high-volume, multi-specification flexible production, helping users transition from standardized assembly to personalized, intelligent assembly.

3.5 Reducing Labor Costs and Assembly Risks

Traditional manual assembly is not only inefficient but also highly dependent on operator skill and has a high error rate. Force-controlled robotic systems, on the other hand, operate efficiently around the clock, improving efficiency while ensuring worker safety and reducing labor costs. Robotic assembly of planetary gears is a task that is both technically challenging and strategically significant. Its high precision and complexity require an assembly system with not only a stable mechanical structure but also real-time sensing and flexible adjustment capabilities. The Dapkon flexible force control system was developed precisely for this purpose. With its powerful sensing and control capabilities, it helps industrial robots break through the bottlenecks of traditional rigid assembly and achieve truly intelligent, flexible, and high-quality assembly.

In the future, as the manufacturing industry continues to pursue higher levels of automation and product quality, robotic force control assembly solutions will demonstrate their unique value in more high-tech fields, driving the entire industrial system towards a higher level of intelligence.

For more information on the application cases and product solutions of Dapkon's robotic flexible force control assembly technology, please contact us. We will provide your company with professional, efficient, and intelligent automated assembly solutions.

http://www.dapkon.ai

dapkon -

AuthorPosts

- You must be logged in to reply to this topic.