- This topic is empty.

-

AuthorPosts

-

2026-01-12 at 2:32 pm #27342

In the cosmetics industry, product purity is not just a quality standard—it is a critical requirement that directly impacts consumer safety and brand reputation. From creams and lotions to serums and powders, cosmetic products demand stringent control over every step of production. One of the most crucial aspects often overlooked is the air supply system used during manufacturing. Contaminated or oil-laden air can compromise product integrity, leading to costly recalls and regulatory penalties. This is where oil-free scroll compressors play an essential role in maintaining air purity in cosmetic production.

Understanding Oil-Free Scroll Compressors

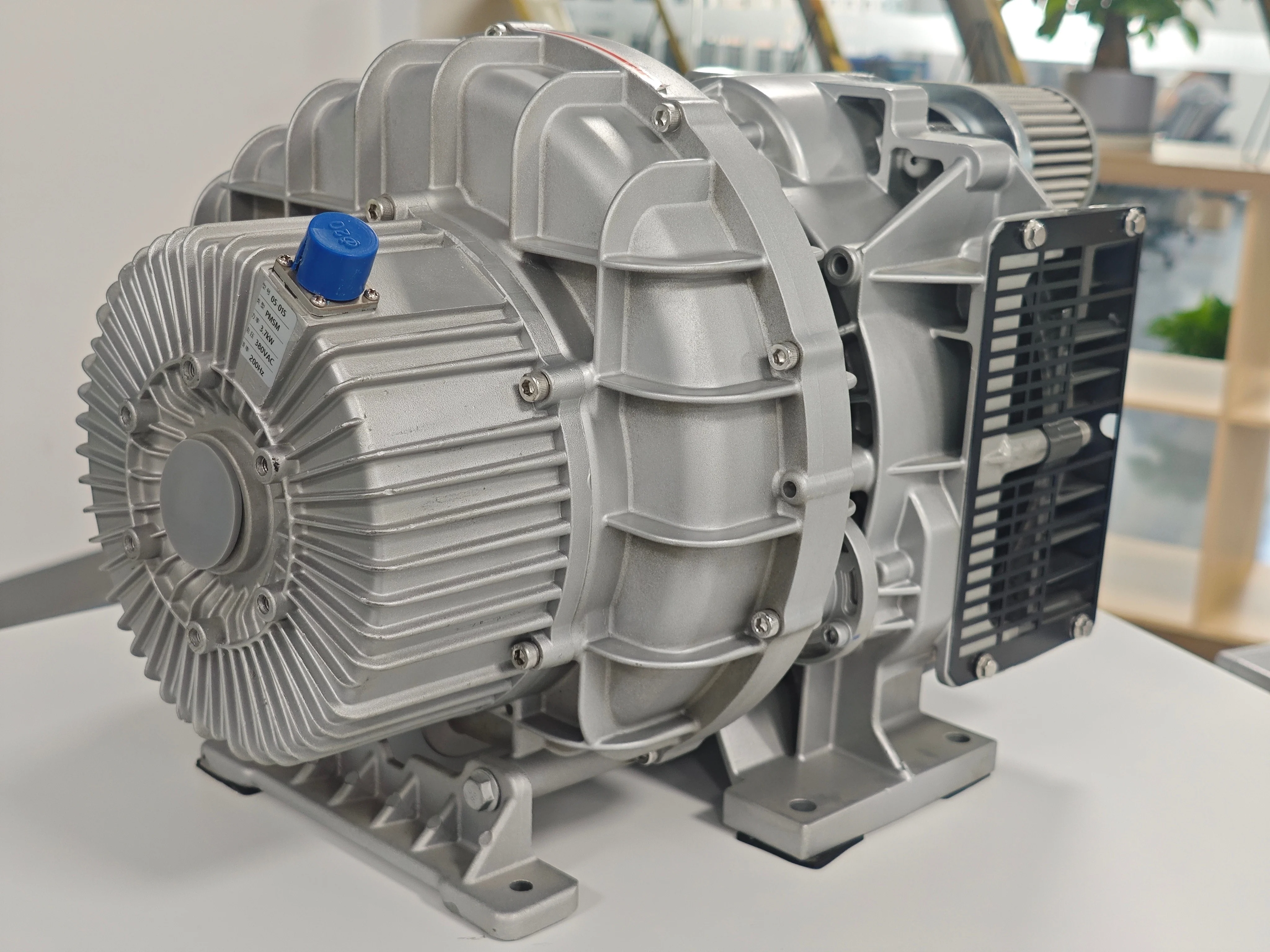

An oil-free scroll compressor is a type of positive displacement compressor that uses two interleaving scrolls to compress air without the need for lubricating oil in the compression chamber. Unlike traditional oil-lubricated compressors, oil-free scroll compressors eliminate the risk of oil contamination in the air supply, making them ideal for applications where hygiene and product purity are critical.

Key features of oil-free scroll compressors for cosmetic manufacturing include:

-

Contamination-free operation: No oil enters the compressed air, ensuring that the air remains clean and suitable for contact with sensitive cosmetic ingredients.

-

Low maintenance: With fewer moving parts and no need for regular oil changes, oil-free compressors reduce downtime and maintenance costs.

-

Energy efficiency: Modern oil-free scroll compressors are designed to deliver high efficiency with stable air delivery, supporting continuous cosmetic production.

-

Quiet operation: Many cosmetic manufacturing facilities are sensitive to noise; oil-free scroll compressors operate quietly, enhancing the working environment.

Importance of Air Quality in Cosmetic Production

In cosmetic production, the quality of compressed air can directly affect product safety. Contaminants such as oil, dust, moisture, and microbial particles can alter the formulation, reduce shelf life, or even cause health hazards for end users. Regulatory authorities, including the FDA and ISO, mandate strict air quality standards for cosmetic production facilities, particularly for cleanrooms and filling operations.

Using clean air compressors for cosmetics ensures that air entering production lines is free from oil and other pollutants. For instance, in the production of moisturizers or facial serums, even a minute trace of oil contamination can cause emulsion instability, affecting texture, appearance, and efficacy. Similarly, in powder or aerosol-based products, compressed air that contains oil or particulates can lead to clumping, inconsistent dosing, or contamination.

Applications of Oil-Free Scroll Compressors in Cosmetic Manufacturing

Oil-free scroll compressors have found widespread application across various stages of cosmetic production:

-

Filling and Packaging: During the filling of bottles, tubes, or jars, compressed air is used to transport and dose products accurately. Oil-free air prevents contamination of the finished product and packaging materials.

-

Mixing and Emulsification: Cosmetic creams and lotions require precise mixing under controlled conditions. Introducing compressed air without oil ensures that emulsions remain stable and free of impurities.

-

Spray and Aerosol Production: For products like deodorants, hair sprays, or facial mists, oil-free air guarantees that spray nozzles operate smoothly without clogging, ensuring consistent product performance.

-

Cleanroom Operation: Many cosmetic factories use ISO-classified cleanrooms. Oil-free scroll compressors in cosmetics industry provide the high-quality, contaminant-free air necessary to maintain cleanroom standards and prevent microbial growth.

Advantages of Oil-Free Scroll Compressors for Cosmetic Manufacturers

Switching to oil-free scroll compressors offers several advantages that go beyond simply meeting regulatory requirements:

-

Enhanced Product Safety: The absence of oil contamination significantly reduces the risk of product defects, recalls, or complaints.

-

Extended Equipment Life: Oil-free operation prevents oil-related wear and tear on production equipment, reducing maintenance needs.

-

Compliance with Industry Standards: Many cosmetic manufacturing standards, including ISO 22716 (Good Manufacturing Practices for cosmetics), require the use of oil-free air in sensitive operations.

-

Sustainability: Oil-free scroll compressors reduce environmental impact by eliminating the need for oil disposal and minimizing the risk of chemical contamination.

Choosing the Right Oil-Free Scroll Compressor

When selecting oil-free scroll compressors for cosmetic manufacturing, several factors should be considered:

-

Airflow and Pressure Requirements: Determine the total air consumption of your production line to ensure the compressor can meet peak demand without fluctuations.

-

Cleanroom Compatibility: For ISO-classified cleanrooms, the compressor should meet air quality standards and operate with minimal noise and vibration.

-

Energy Efficiency: Consider compressors with variable speed drives or energy-saving modes to reduce operational costs.

-

Reliability and Support: Opt for compressors from reputable manufacturers that offer maintenance support, spare parts, and warranty services.

Maintenance Best Practices

Even though oil-free scroll compressors require less maintenance than oil-lubricated alternatives, regular upkeep is essential to maintain air purity and equipment longevity:

-

Regular Filter Replacement: Ensure that air intake and outlet filters are clean and replaced according to manufacturer guidelines.

-

Monitoring Air Quality: Periodically test the compressed air for moisture, particulate, and microbial contamination.

-

Routine Inspections: Check scroll elements, bearings, and seals for wear or damage.

-

Environmental Considerations: Maintain a clean and dry compressor room to prevent external contamination.

Future Trends in Cosmetic Production Air Systems

With the cosmetic industry evolving towards higher safety standards and sustainable practices, the demand for oil-free scroll compressors in cosmetics industry is expected to grow. Key trends include:

-

Integration with Smart Factory Systems: Advanced compressors can now be integrated with IoT monitoring for real-time performance and predictive maintenance.

-

Energy Optimization: Manufacturers are increasingly adopting compressors with variable frequency drives to reduce energy consumption without compromising air quality.

-

Compact and Modular Designs: Smaller production lines benefit from compact oil-free scroll compressors that are easy to install and maintain.

Conclusion

In cosmetic production, air quality is a critical factor that directly affects product purity, safety, and regulatory compliance. Oil-free scroll compressors provide a reliable, maintenance-friendly, and contamination-free air supply, making them an indispensable choice for cosmetic manufacturers. From filling and mixing to cleanroom operation, these compressors protect product integrity while supporting efficient, sustainable production.

Investing in high-quality oil-free scroll compressors ensures that cosmetic brands can deliver safe, consistent, and high-performing products to consumers, maintaining trust and competitiveness in an increasingly demanding market. For any cosmetic manufacturer seeking to enhance product purity, reduce contamination risks, and comply with international standards, oil-free scroll compressors represent a smart and future-proof solution.

http://www.glcompressor.com

glcompressor -

-

AuthorPosts

- You must be logged in to reply to this topic.