- This topic is empty.

-

AuthorPosts

-

2025-12-02 at 6:03 pm #26862

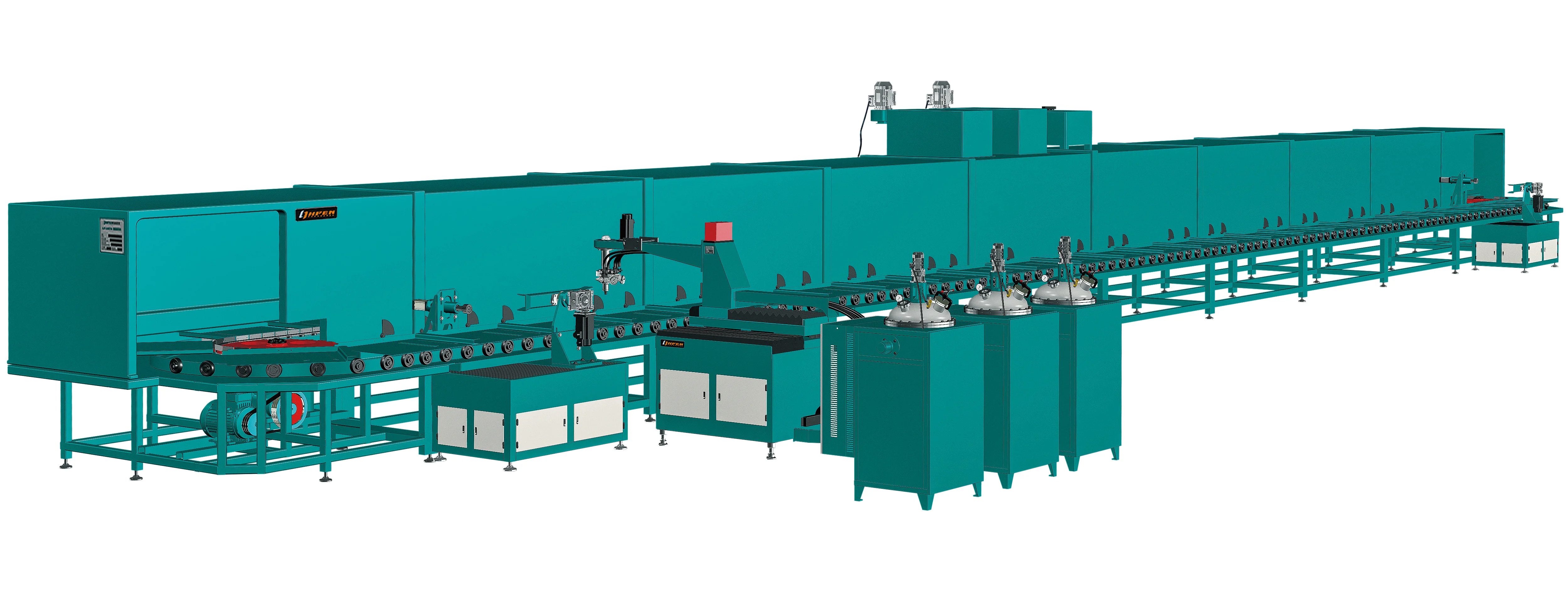

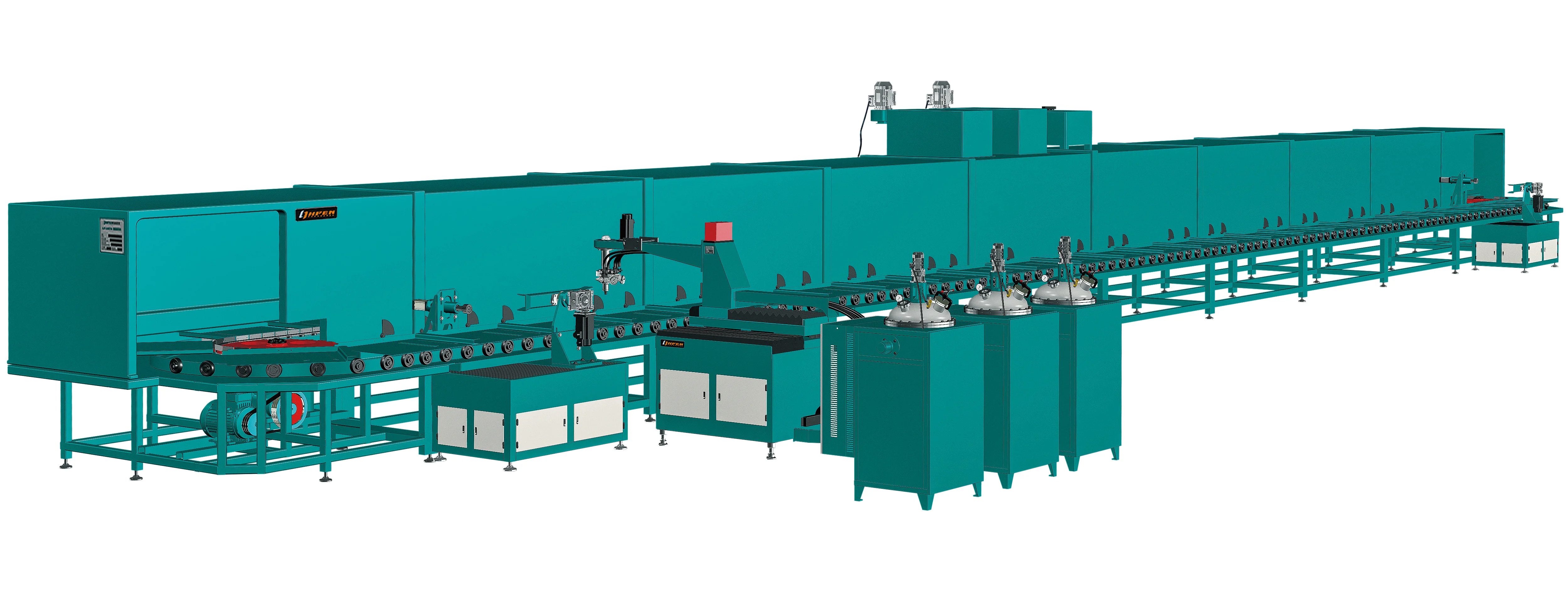

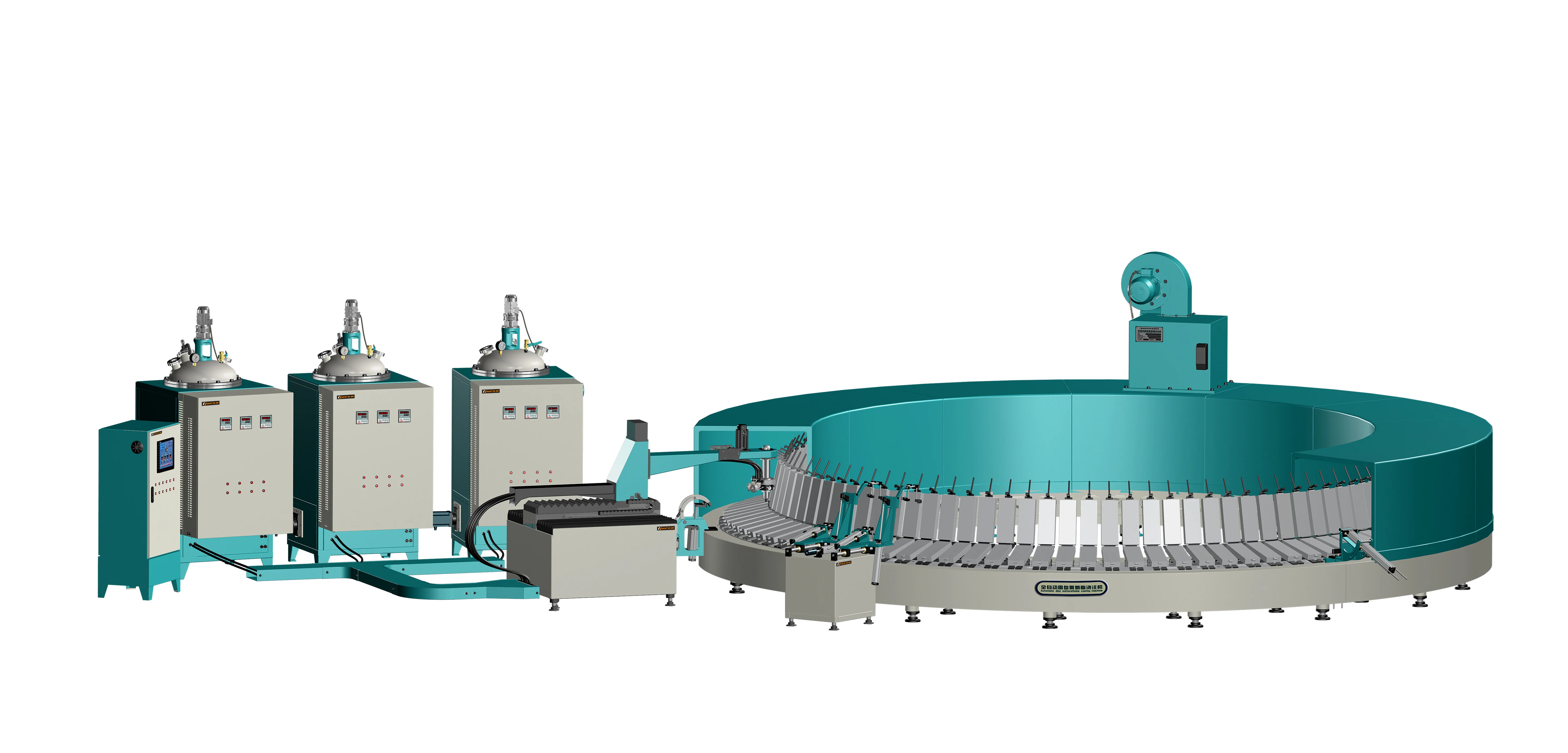

Selecting a high-quality low-pressure foaming machine is essential for manufacturers who prioritize precision, stability, and long-term performance in polyurethane (PU) production. With applications ranging from insulation panels and furniture to automotive interior components, the right equipment can significantly improve production efficiency and product consistency. In this expert guide, we will walk through key considerations when choosing a low-pressure foaming machine while introducing Haifeng, one of the leading manufacturers of polyurethane production and processing equipment and integrated system solutions.

Understanding the Role of a Low-Pressure Foaming Machine

A low-pressure foaming machine is a critical piece of PU processing equipment designed for mixing and dispensing polyurethane components under stable, controlled conditions. This type of machine is widely used due to its versatile application range, user-friendly operation, and cost-effective maintenance.

High-quality machines ensure uniform material mixing, excellent foam structure, and reliable production cycles—factors that directly impact product strength, insulation performance, and overall quality.

Key Features to Look For in a High-Quality Machine

When selecting a machine, pay attention to the following essential characteristics to ensure precision, durability, and process optimization.

Mixing Accuracy and Stability

Consistent and precise mixing is the heart of a good foaming machine. A superior system should feature:

-

Stable and repeatable mixing ratios

-

Efficient mechanical mixing heads

-

Smooth and responsive flow control

Manufacturers like Haifeng engineer their mixing systems with advanced flow technology to guarantee uniformity and minimize material waste.

Intelligent Control Systems

Modern production demands automation and real-time monitoring. A reliable machine should include:

-

Smart digital control panels

-

Fault detection and alert systems

-

Adjustable pouring parameters

Haifeng’s control solutions are known for their intuitive interfaces and dependable automation that enhances workflow efficiency.

High-Quality Components and Build

Durability and longevity depend on the overall construction quality. A premium machine will incorporate:

-

Precision-machined parts

-

Strong and corrosion-resistant materials

-

Stable mechanical structures

Haifeng’s equipment is recognized for its robust, industrial-grade design that supports long-term high-frequency operation.

Energy Efficiency and Performance

A well-engineered system should reduce energy consumption while maintaining high output. Features such as optimized pump systems, efficient heating modules, and well-designed insulation contribute to superior performance and lower operational costs.

Customization and System Integration

Every production environment has unique needs. The ability to customize tank sizes, mixing configurations, and peripheral systems (like mold carriers, conveyors, and production lines) is an important advantage.

As a manufacturer capable of delivering complete polyurethane equipment solutions, Haifeng provides tailored system engineering to meet specialized application requirements.

Why Consider Haifeng as Your Equipment Partner

As one of the reputable polyurethane production and processing equipment manufacturers, Haifeng stands out for its comprehensive product lineup, exceptional engineering, and dedication to innovation. The company’s low-pressure foaming machines are known for being:

-

Reliable: Designed for stable and continuous operation

-

Efficient: Engineered for optimized material usage and energy performance

-

Precise: Built with accurate metering and advanced control systems

-

Durable: Manufactured using high-strength, long-lasting components

-

Customizable: Adaptable for various PU applications and manufacturing environments

Whether used for insulation materials, automotive accessories, home products, or specialty foam components, Haifeng’s equipment delivers consistent quality and production efficiency.

Final Thoughts

Choosing a high-quality low-pressure foaming machine is an investment that directly affects product consistency, production speed, and long-term operational cost. By evaluating factors such as mixing accuracy, construction quality, automation level, and customization potential, manufacturers can find a solution that truly matches their needs.

With its strong engineering background, advanced production systems, and commitment to excellence, Haifeng remains a reliable partner for companies seeking professional, efficient, and high-performance polyurethane foaming solutions.

A well-chosen machine will not only elevate your production capabilities but also lay the foundation for improved product quality and sustainable growth.

Understanding the Applications of Low Pressure Foaming Machines Across Industries

http://www.haifeng-automation.cn

Haifeng -

-

AuthorPosts

- You must be logged in to reply to this topic.