- This topic is empty.

-

AuthorPosts

-

2025-10-16 at 10:08 am #26364

In today’s competitive automotive industry, manufacturers are constantly seeking ways to improve performance, reduce weight, and increase reliability of vehicle components. High precision aluminum die casting has emerged as a game-changer, enabling the production of complex, lightweight, and highly durable parts with tight tolerances.

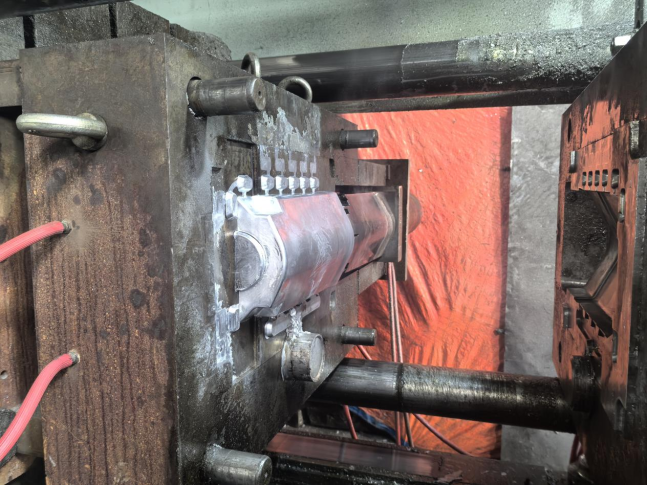

Tiger Casting, a leader in the field, specializes in producing auto parts, agricultural components, machinery parts, lighting fixtures, and hardware fittings using both aluminum die casting and aluminum gravity casting. With advanced machinery, high-precision CNC centers, and rigorous quality inspection protocols, Tiger Casting is setting new standards in the automotive manufacturing sector.

This article explores how high precision aluminum die casting is transforming the automotive industry and how Tiger Casting leverages its expertise to deliver enhanced performance components.

1. What Makes High Precision Aluminum Die Casting Ideal for Automotive Parts

Aluminum die casting combines the lightweight properties of aluminum with the strength and precision of modern casting technologies, making it perfect for automotive applications:

-

Lightweight yet strong: Reduces vehicle weight, improving fuel efficiency and lowering emissions.

-

High dimensional accuracy: Ensures tight tolerances for complex parts like engine blocks, transmission housings, and structural brackets.

-

Smooth surface finish: Minimizes machining needs and improves aesthetic and functional quality.

-

Versatility: Can produce components ranging from small fittings to large structural parts.

By leveraging high precision die casting, automotive manufacturers can optimize both performance and production efficiency.

2. Tiger Casting’s Advanced Manufacturing Capabilities

Tiger Casting’s commitment to precision and quality is supported by its state-of-the-art manufacturing infrastructure:

-

Casting Machines: Ensure high consistency and repeatability for aluminum die-cast components.

-

High Precision Machining Centers & CNC Lathes: Achieve tight tolerances on complex geometries.

-

Automatic Drilling and Tapping Machines: Streamline secondary machining processes.

-

Polishing and Shot Blasting Machines: Enhance surface quality for both functional and aesthetic requirements.

These technologies allow Tiger Casting to produce high-precision automotive parts that meet stringent OEM standards while maintaining cost efficiency.

3. Quality Assurance and Testing

Precision casting requires not only advanced machinery but also rigorous quality inspection. Tiger Casting employs a comprehensive quality assurance process:

-

Spectrometer: Verifies material composition.

-

Roughness Meter and Hardness Meter: Ensures surface integrity and mechanical properties.

-

Measuring Projector & Measuring Tools: Confirms dimensional accuracy.

-

Tensile Test Machine: Tests structural strength.

-

X-ray Detector & Leak Test Machines: Detects internal defects and ensures part integrity.

This combination of inspection techniques guarantees that every automotive part delivered is reliable, high-performance, and defect-free.

4. Applications in Automotive Manufacturing

High precision aluminum die casting is revolutionizing multiple areas of automotive manufacturing:

-

Engine Components: Lightweight engine blocks, cylinder heads, and housings improve fuel efficiency.

-

Transmission Parts: High dimensional accuracy ensures smooth operation and durability.

-

Structural Components: Chassis brackets and supports gain strength without adding unnecessary weight.

-

Electrical and Lighting Housings: Complex geometries for modern lighting and sensor enclosures are possible with high precision casting.

By enabling complex designs, Tiger Casting helps OEMs innovate while keeping production scalable and cost-effective.

5. Advantages Over Traditional Casting Methods

Compared to traditional sand casting or gravity casting, high precision aluminum die casting offers:

-

Tighter tolerances: Less post-processing and machining required.

-

Better surface finish: Reduces finishing time and improves part quality.

-

Higher production efficiency: Fast mold cycles for large-scale manufacturing.

-

Material efficiency: Reduces waste and lowers material costs.

These advantages make die-cast aluminum components a preferred choice for modern automotive design.

6. Enhancing Performance and Reliability

The combination of lightweight materials, tight tolerances, and high surface quality directly contributes to:

-

Vehicle performance: Lower weight improves fuel efficiency and handling.

-

Durability: Strong, precisely cast components withstand stress and wear.

-

Safety: Reliable structural and engine parts reduce the risk of failure.

-

Cost savings: Efficient production and minimal scrap reduce manufacturing costs.

Tiger Casting ensures that every component delivered meets these performance and reliability benchmarks.

7. Innovations and Custom Solutions

Tiger Casting goes beyond standard components by offering custom high precision aluminum die casting solutions:

-

Tailored designs for complex automotive assemblies.

-

Multi-step casting and machining integration for tight tolerance assemblies.

-

Collaboration with OEMs for innovative material and design applications.

These innovations enable automotive manufacturers to push the boundaries of vehicle design and engineering.

8. FAQ Section

Q1: What is high precision aluminum die casting used for in automotive manufacturing?

A: Engine components, transmission housings, structural brackets, lighting housings, and various small to large auto parts.Q2: How does Tiger Casting ensure consistent quality in die-cast parts?

A: Through advanced machinery, CNC machining, automated processes, and comprehensive inspection tools including X-ray, spectrometer, and tensile testing.Q3: What are the advantages over traditional casting methods?

A: Tighter tolerances, better surface finish, faster production, and reduced material waste.Q4: Can Tiger Casting produce customized automotive parts?

A: Yes, Tiger Casting provides tailor-made die-cast solutions for complex assemblies and OEM specifications.Q5: How does aluminum die casting improve vehicle performance?

A: By reducing weight, increasing strength, enhancing durability, and improving fuel efficiency.

Conclusion

High precision aluminum die casting is redefining automotive parts manufacturing, offering unmatched precision, efficiency, and performance. With advanced machinery, skilled engineering teams, and stringent quality control, Tiger Casting delivers reliable, high-performance components that meet the evolving demands of the automotive industry.

From engine blocks to lighting housings, Tiger Casting’s expertise ensures that every part is lightweight, durable, and precisely engineered, giving manufacturers the confidence to innovate and excel in a competitive market.

http://www.tiger-aluminumcasting.com

NINGBO TIGER CASTING COMPANY -

-

AuthorPosts

- You must be logged in to reply to this topic.